等离子切割除尘装置支撑结构优化设计

打开文本图片集

中图分类号:TH122 文献标志码:B DOI:10.19710/J.cnki.1003-8817.20240309

Optimal Design of Support Structure of Plasma Cutting Dust Removal Device

Ma Xudong',Gao Wenqiang',Sun Li² (1.MechanicalEngeringIsitute,ChangchunAutomobileIndustryInstitute,Changchun303;2.FAWJiefangAutomobileCo, Ltd., Changchun 130011)

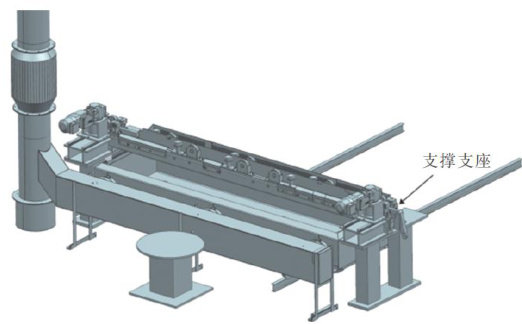

Abstract: The support base is an important structure for the stable operation of the plasma cutting dust removal device.Inorder to enhance operation stability this device,this paper makes a structural optimization analysis of the support base based on the ANSYS Workbench software,including sensitivity analysis for design parameterof each structure,and identified 3factors which have the greatest influenceon the stable operation of support base,namely upper wall tickness,support wall thicknessand support height.Asecond-order mathematical responsesurfacemodel isconstructedbasedontheexperimentaldesignmethods,and iterativeoptimizationismadethroughmulti-objective genetic algorithm.The simulation results show that the natural frequency of the bearing increases by 20.47% and the maximum stress concentration decreases by 6.57% .Theoptimal Pareto solution of the parameter variables is achieved withinthedesignrequirementsandthedurabilityofthebeam issignificantlyimproved,which meets theoptimization requirements.

Keywords:Design parameter optimization,Sensitivity analysis,Response surface method,Multiobjective optimization

1前言

构件对设备静力学性能影响尤为显著[3-4],其中,立面支撑支座在工作时受到压力和切向应力,且工作中受等离子切割、电机振动和风道气体流动的影响,由于其工作环境恶劣、制造工艺和安装条等离子切割除尘装置是集成流体力学、静力学、动力学和材料学的复杂系统机构[1-2]。(剩余6273字)