需求随机条件下冷藏集装箱堆场机修工路径优化

打开文本图片集

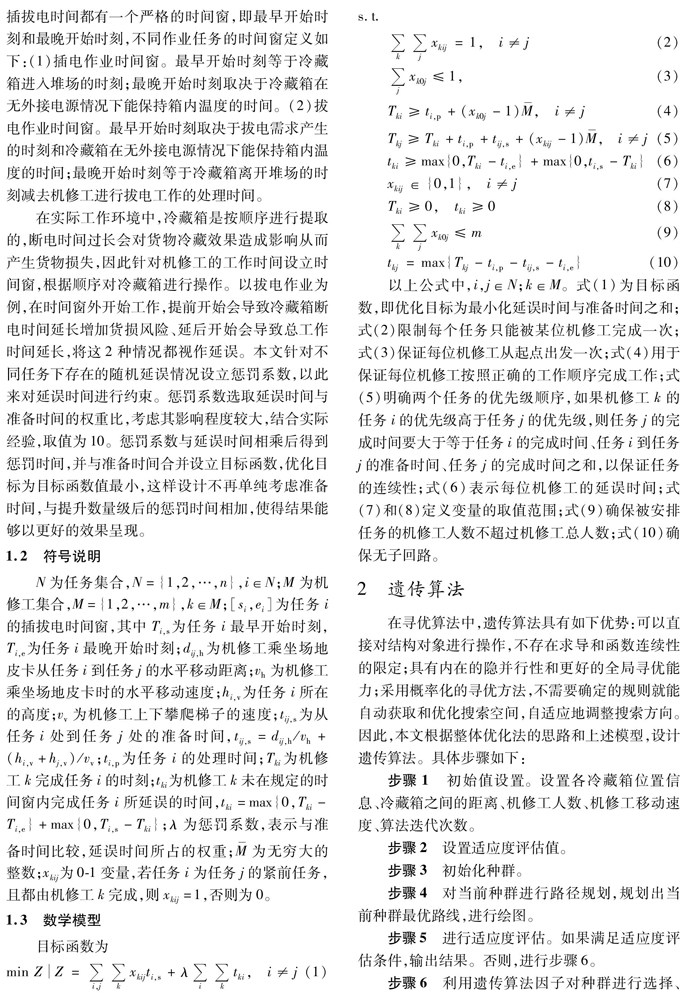

摘要:由于在集装箱码头堆场冷藏集装箱插拔电需要由机修工手动完成,为降低未能及时对冷藏集装箱插电而造成箱内货物腐败的风险,对机修工路径进行优化来减少总完工时间。建立考虑机修工的准备时间和惩罚时间的机修工插拔电路径规划模型,选用遗传算法对模型进行求解。通过算例实验证明了模型和算法的有效性。

关键词: 冷藏集装箱; 带有时间窗的旅行商问题; 路径优化; 遗传算法

中图分类号: U691+.31文献标志码: A

Mechanic path optimization of reefer container yard

under random demand

Abstract: As the power supply connection and disconnection operation of reefer containers in the container terminal yard needs to be manually completed by mechanics, in order to reduce the risk of cargo corruption caused by the failure to timely connect reefer containers to power supply, the mechanic path is optimized to reduce the total completion time. A mechanic path planning model for the power supply connection and disconnection operation is established considering the preparation time and the penalty time of mechanics. The model is solved by the genetic algorithm. The effectiveness of the model and the algorithm is proved by numerical examples.

Key words: reefer container; traveling salesman problem with time window; path optimization; genetic algorithm

引言

伴随着食品冷链物流的市场规模越来越大,越来越多的冷藏集装箱(简称“冷藏箱”)需要在相对较短的时间内进行转运。(剩余8267字)