煤灰渣混凝土梁柱节点抗震性能研究

打开文本图片集

中图分类号:TU375.4 文献标识码:A DOI:10.7535/hbkd.2025yx04010

Seismic performance of coal ash slag concrete beam-column joints

WEI Jiaqi1,ZHANG Mingqian1,WANG Zhuo1,MA Kang1,YUHaifeng 1 ,FENG Y LI Huawei²,NIE Qingke²,CAO Kangjia1

(1.School of Civil Engineering,Hebei Universityof Science and Technology,Shijiazhuang,Hebei O5oo18,China; 2.Research Center for Geotechnical Engineering Technology of Hebei Province/Key Laboratory for Industrial Solid Waste Comprehensive Utilization of Hebei Province,China Hebei Construction &. Geotechnical Investigation Group Limited,Shijiazhuang,Hebei O50227,China)

Abstract:Toivestigate the high-valueand high-dose utilizationofsolid waste gasification ashinconcretecomponents,lowcyclereciprocating loading tests were performedonjoints within one ordinary concrete and threegasifiedash concrete beamcolumn oints.The failure modes,hystereticbehavior,energydisipation,ductityand stiffessdegradation were studied. The failure mechanisms of concrete jointswithcoal ashasanadmixture wereexplored,and theefectsof dosage,axial compressionratio,as wellasconcrete strengthon the seismic performanceof thesejoints were analyzed.Theresults reveal thatplastic hinge failureatthebeamendsoccurs inallofthecoalashslagconcrete joints.During thisprocess,the reinforcement yieldsand theconcreteis crushed,which includes fourstages:initialcracking,extensivecracking,ultimate strength andfailure.The hysteresis curves of the specimens are relatively full.When the dosage ratioofcoalash slagis 20% , the bearing capacity of joints made with coal ash slag concrete increases by 14% compared to those made with ordinary concrete.Using properdesignedcoalashslagconcretecanimprovethebearingcapacitywhileconserving cement,andlowering carbonemisions inconcrete,which providessomereferencefortheargescaleandhigh-valueutilizationofsolidwastecoalash in concrete engineering.

Keywords:concreteand reinforced concrete structures;coal gasificationash residue;quasi-static test;axial compresior ratio;seismic performance;bearing capacity

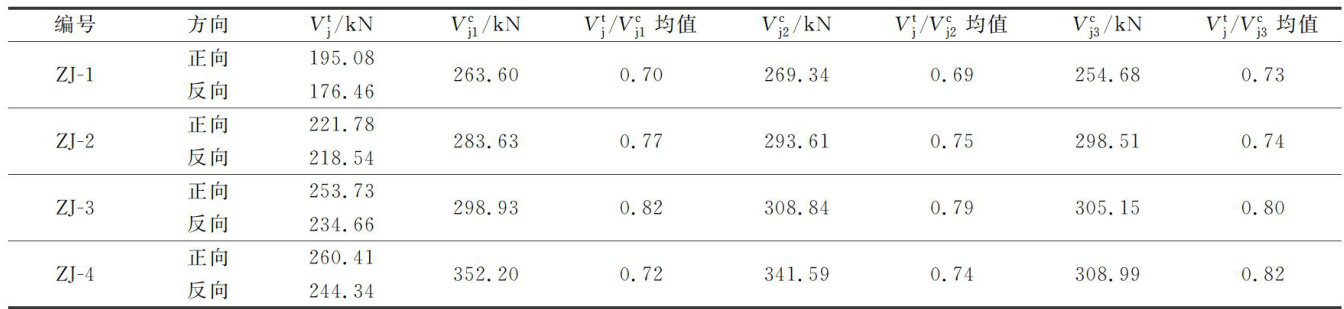

煤灰渣是由多种化学组分构成的复杂体系,其中 SiO2∙Al2O3∙CaO∙Fe2O3 是煤灰渣中的主要成分,质量分数的总和通常在 80% 以上[1]。(剩余12762字)