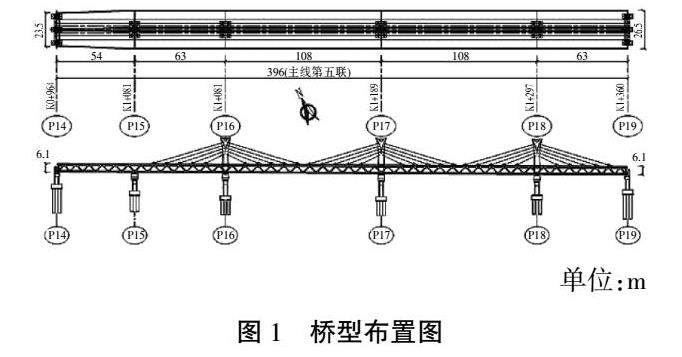

双层钢桁梁三矮塔斜拉桥拼装工艺设计

打开文本图片集

摘 要:在已有的钢桁梁拼装施工技术中,从分段划分、组装、工装、拼装顺序、焊接变形控制及检测等方面进行研究。总结“单元件制造+单元件地面拼装为大节段+大节段总装+节点自适应顶推+分阶段检测验收”工艺在赣州蟠龙大桥项目的成功应用。

关键词:双层钢桁梁;预调;焊接变形;钢结构检测;拼装工艺

中图分类号:TU758.11 文献标志码:A 文章编号:2095-2945(2023)18-0112-05

Abstract: In the existing construction technology of steel truss girder assembly, through studies from the aspects of segment division, assembly, tooling, assembly sequence, welding deformation control and inspection, the technology of "single element manufacturing + single element ground assembly for large segment + large segment general assembly + node adaptive push + stage inspection and acceptance" is summarized, which has been successfully applied in the project of Panlong Bridge in Ganzhou.

Keywords: double-layer steel truss girder; preset; welding deformation; steel structure inspection; assembly process

钢桁梁施工工艺有“地面拼装、整体提升、高空滑移”“钢桁梁大节段水运、悬臂拼装”[1-2]“钢桁梁大节段水运、浮吊整体吊装法”[3]“地面拼装、转体法”[4]“场内分段制作+现场整体拼装+浮托顶推滑移”[5]5种施工方式,总结起来分为2类:工厂单元件制作+桥位总装+架设工艺;工厂大节段制作+架设工艺。(剩余5217字)