立轮辅助钻进单元试验与数值模拟分析

打开文本图片集

中图分类号:TE921 文献标识码:A DOI:10.12473/CPM.202402062

YangYan,Huang Kuilin,Song Dongdong,et al.Test and numerical simulation analysis of vertical whel assisteddrilling unit[J].China Petroleum Machinery,2025,53(5):48-55.

Test and Numerical Simulation Analysis of Vertical Wheel Assisted Drilling Unit

Yang Yan1,2.3Huang Kuilin 1,4 Song DongdongHuang Zequan° Qiu Shunzuo 1,2 Hu Jiaqi² (1.MOEKeyLaboratoryforOilndGasEquipment,SouthwestPetroleum University;2.Facultyof IntenationalApliedTechnoogy,Yibin University;3.YibinEngnering TechnologyResearchCenterforFlexibleProductionLine ManagementandService; 4.SchoolofMechanicalEngineering,SouthuestPetroleumUniversity;5.CCDCChuanxiDrilingCompany;6.FacultyofIntellnt Manufacturing, Yibin University)

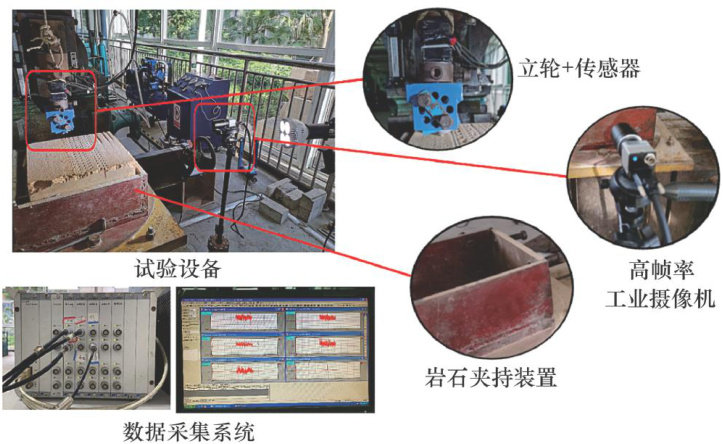

Abstract: In difficult-to-drilldeep formations,PDC bits struggle to penetrate and have low rock-breaking efficiency,and provide poor bit azimuth stability in stering driling.This paper presents a PDCbit with a wheel and axle integrated vertical wheel cutting structure.PDC rock-breakingunit was tested under vertical wheel predamage conditions at variable cuting depth to compare the PDC rock-breaking effects under PDC paralel cutting and vertical wheel pre-damage conditions.Moreover,numerical simulation analysis was conducted to reveal the working mechanism of vertical wheel assisted drilling.The research results show thatthe tangential and axial dynamic load factors of vertical wheel assisted PDC rock cutting are 43.31% and 36.63% lower respectively than PDC rock cutting alone.During the rock breaking process,the cutter of the vertical wheel periodically participates in intermittent cutting,and the cuting state undergoes periodic changes,exhibiting obvious“milling”characteristics.The vertical wheel and PDC cutteron the vertical wheel type PDC bit scrape and cut rocks in a nonparallel way,forming a spiral downhole morphology,which helps PDC cuter to invade rocks and improve rock breaking efciency,The vertical whel cutting structure plays a role of sharing pressure and cushioning for PDC cutter,improving the overallstabilityand service life of the bit.The research results contribute toa deep and thorough understanding of the complex motion and working mechanics characteristics of vertical wheel type PDC bit.

Keywords: PDC bit; working mechanism; vertical wheel; milling; share pressure and cushion

0引言

我国大部分未开发的油气资源埋藏在深层[1-3],PDC 钻头 + 导向钻井技术广泛应用于深井、超深井的油气开发中,可大大提高深井油气产量,降低综合成本[4-5]。(剩余11023字)