真空膜蒸馏浓缩黄芩苷提取液过程中的膜污染机制

打开文本图片集

中图分类号:TU992.3 文献标志码:A

Membrane Fouling Mechanism During Concentration of Baicalin Extract by Using Vacuum Membrane Distillation Technology

SHAO Ruonan 1 ,YU Jun 2 ,ZHU Youbing 3 , LIU Chao 1 , LIU Guicail (1.School of Civil Engineering and Architecture,University of Jinan,Jinan 25OO22,Shandong,China; 2.Qingdao Jiaozhou Construction Engineering Design Co.,Ltd.,Qingdao 2663Oo,Shandong,China; 3.Shanghai Urban Construction and Municipal Engineering Group Co.,Ltd.,Shanghai 2Ooo65,China)

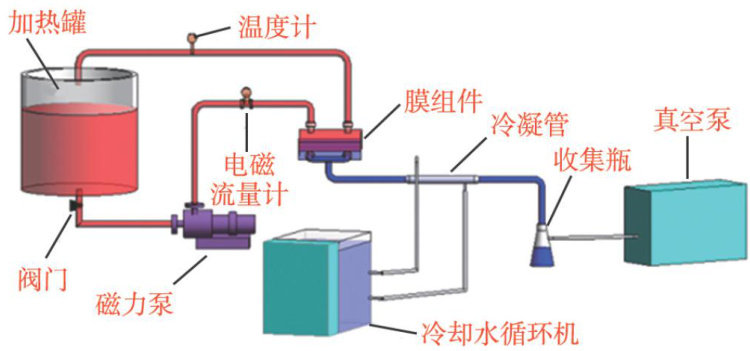

Abstract:To investigate membrane fouling issues in a vacuum membrane distilation system,membrane flux and baicalin retentionratio were selected as indicators to evaluate eficiencyof the system.Feed temperature,vacuum pressre,and feedflowrate were chosen as process parameters of the system,and orthogonal experiments wereused tooptimize the three processparameters.Onthebasis of theoptimized process parameters,efects of diferent process parameterson efficiencyof the system were explored. Morphology and elemental composition of membrane surface were analyzed by using scanning electron microscopy -X -ray energy dispersive spectroscopy to reveal intrinsic relationships between membrane fouling and processparameters.Theresultsshow that theoptimal process parameters for thesystem are feed temperature of 60 C ,vacuum pressure of O.09 MP a ,and feed volume flow rate of 600L/h . When the feed temperature increases from 40‰ to 60‰ ,decrease rate of membrane flux relative to the initial value at the end of system operation increases from 71.05% to 79.18% . When the vacuum pressure increases from O. O7 MPa to 0. O9 MPa, the decrease rate increases from 71.63% to 79.18% . When the feed volume flow rate increases from 4Oo L/h to 600L/h ,the decrease rate decreases from 83.49% to 79.18% . An increase in feed flow rate mitigates the membrane fouling,whereas an increase in feed temperature or vacuum pressure intensifies the membrane fouling.

Keywords:vacuum membrane distilation;membrane fouling mechanism;baicalin extract;orthogonal experiment;membrane flux;retention ratio

近年来,中药产业在迎来新的发展机遇的同时也面临许多挑战,例如,中药浓缩工序的水资源消耗大,有效成分被高温破坏等[1]。(剩余9205字)