含孔洞复合材料结构的拉伸性能仿真

打开文本图片集

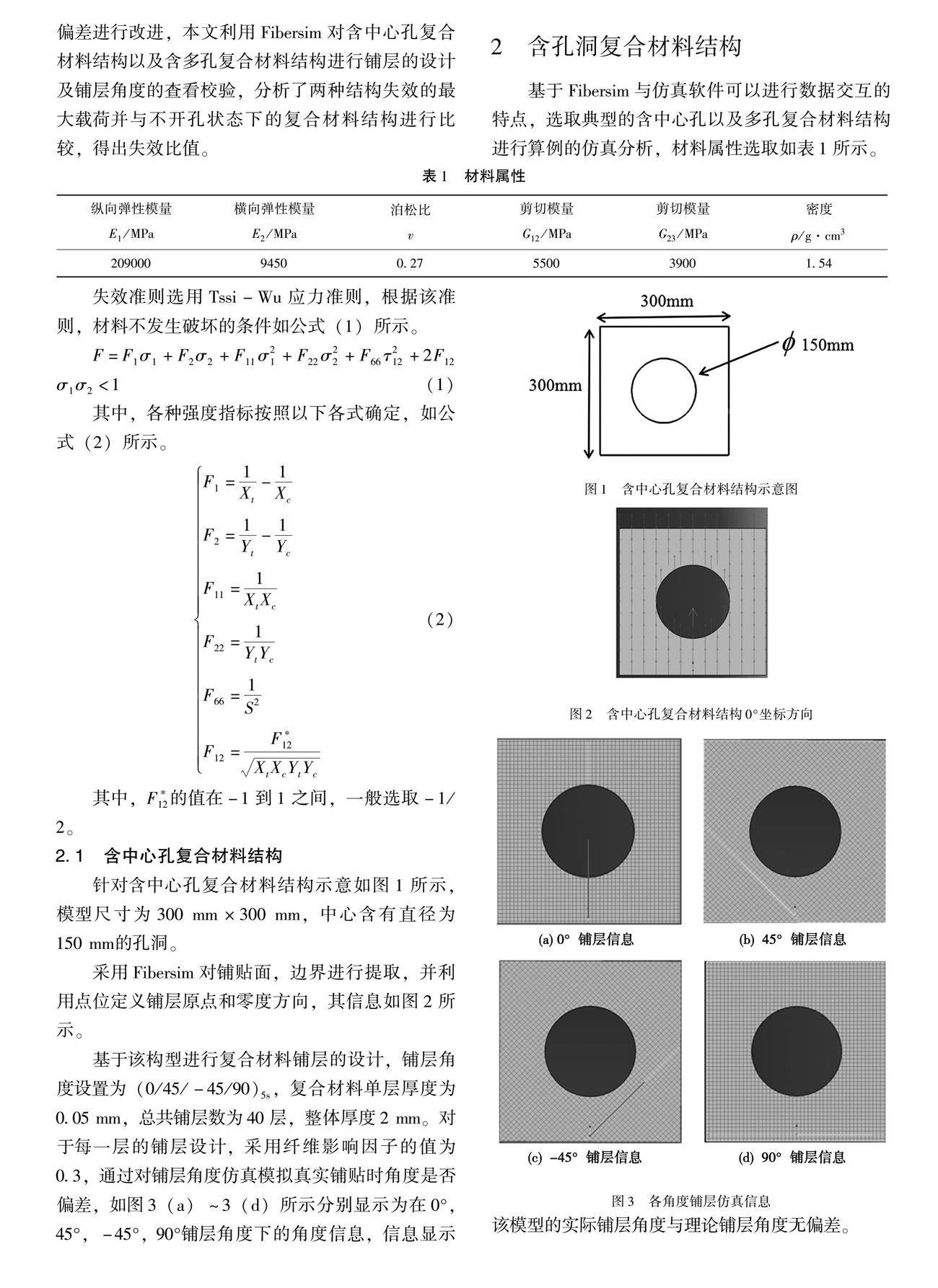

摘 要 本文针对含中心孔洞和含多孔复合材料结构模型,利用Fibersim进行铺层设计并检验铺层角度是否偏差,对于含中心孔洞复合材料结构采用分区域铺覆的设计方法进行探究,发现可以达到在制造中节省材料成本的作用。将两种结构进行仿真失效计算同时与不开孔状态的复合材料结构进行比较,得出失效比值。

关键词 Fibersim;有限元仿真;复合材料;铺层设计

Simulation of Tensile Properties of Composite

Structures Containing Holes

CHEN Yinghan, LIU Jiaqiu, YU Baifeng, LIU Jia, HAO Chenwei

(Harbin FRP Institute Co.,Ltd., Harbin 150028)

ABSTRACT In this paper, we use Fibersim to design the lay-up for center hole and porous composite structure model, check whether the layup angle is deviated or not, and explore the design method of lay-up by area for center pore composite structures, and find that it can achieve the role of saving the material cost in manufacturing. The two structures were subjected to simulated failure calculations while comparing them with the composite structure in the unopened state to derive the failure ratio.

KEYWORDS fibersim; finite element simulation; composite material; lay-up design

通讯作者:陈英函,硕士,助理工程师。(剩余3745字)