回转体零件内部误差工业CT图像测量

打开文本图片集

doi:10.37188/OPE.20253304.0557 CSTR:32169.14.OPE.20253304.0557

Measurement method for internal error of rotary parts using industrial CT images

JIANG Yijun 1,2. ,LIU Zexin 1,3 , LIU Xueshuan 4 ,LONG Chao 1,3 , DUAN Liming 1,2 , CAI Yufang 1,3*

(1. ICT Research Center,Key Laboratory of Optoelectronic Technology and Systems , Ministry ofEducation,Chongqing University,Chongqing 4OoO44,China; 2. College ofMechanical and Vehicle Engineering, Chongqing University, Chongqing 4OoO44,China; 3.College of Optoelectronic Engineering, Chongqing University, Chongqing 4OoO44, China; 4. Project Management Center,Equipment Department ofRocket Force,Beijing 1Oo085,China) * Corresponding author,E-mail: caiyf@cqu. edu. cn

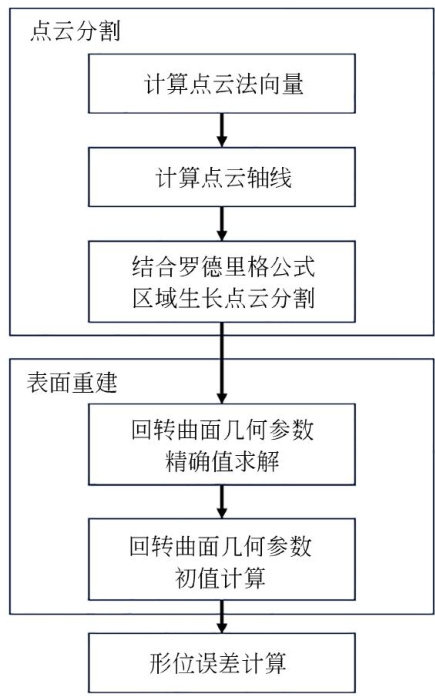

Abstract:To address the issue of internal error measurement for rotary components,this paper exploited the advantages of industrial CT,which is non-destructive and capable of detecting the internal structure, and achieved the internal eror measurement of rotary components through industrial CT images.Firstly, the axis parameters of the rotary body were calculated,and these parameters and Rodrigues’s formula were incorporated into the region growing method to enhance the accuracy of 3D point cloud segmentation. Subsequently,the objective function of the geometric model was established,and initial parameters of the geometric model were obtained through least squares linear fiting. Further,the optimal parameters of the geometric model were solved using Levenberg-Marquardt nonlinear fiting. Finally,the geometric model was utilized to compute the shape and position errors of the parts. Experimental results demonstrate the superiority of the proposed point cloud segmentation method in terms of accuracy when compared to othermethods.Additionally,the surface reconstruction method exhibits better stability than the RANSAC algorithm. Compared with commercial VG software,the accuracy of shape and position error calculation is higher,with an increase of 8.5% in cylindricity,21. 1% in coaxiality,and 4.1% in verticality.Moreover,the cone tolerance calculation yields results within the design specifications,which satisfying the requirements of error measurement engineering.

Key words: computed tomography; point clouds segmentation; surface reconstruction; error measure-ment

1引言

回转体零件,如燃油喷嘴、轴承和主轴等,在工业制造中占据重要地位,其几何精度和结构完整性直接关系到最终产品的性能与可靠性。(剩余14055字)