关于粉煤气化配套制氨组合变换工艺设计思路的研究

打开文本图片集

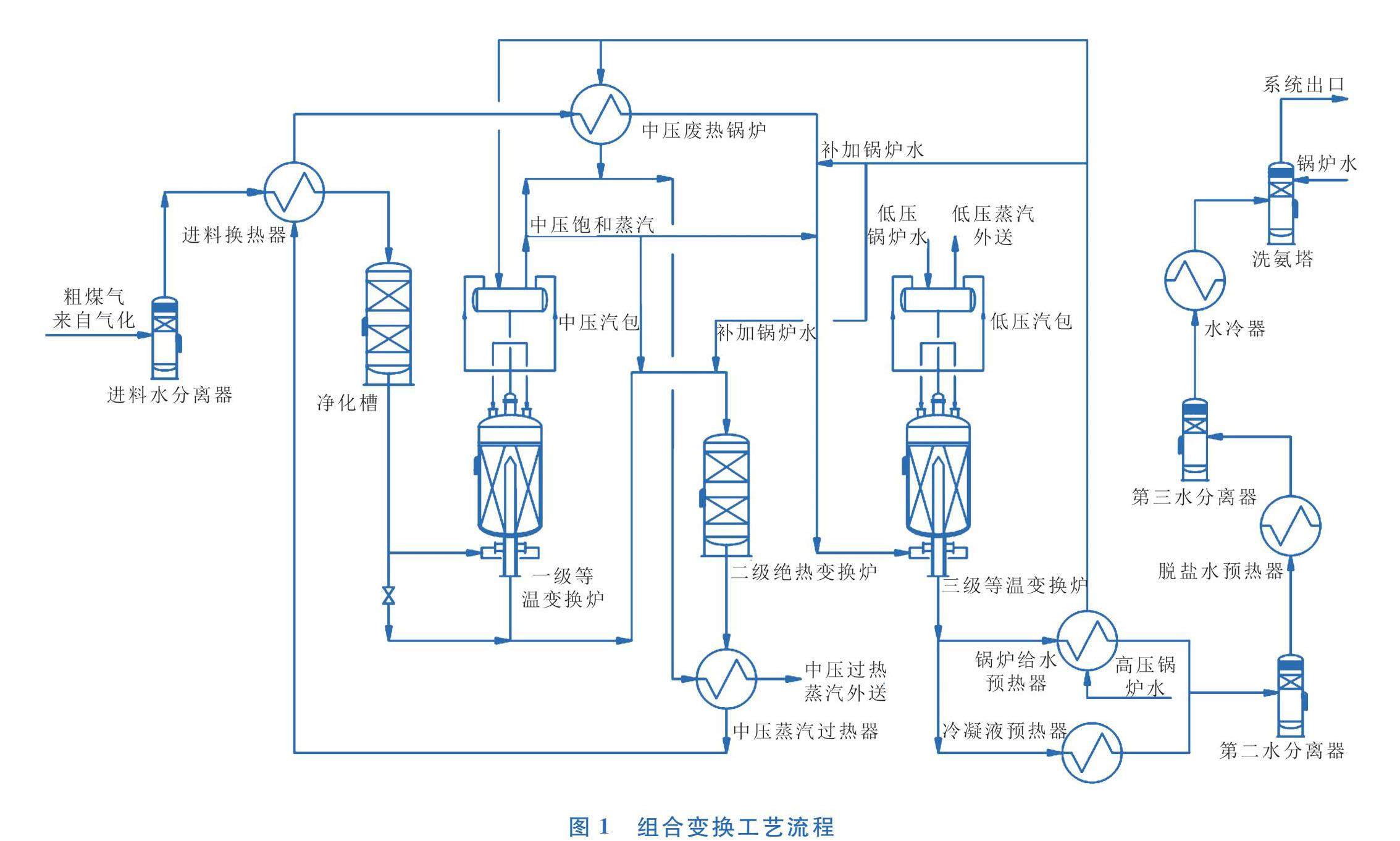

摘 要:针对粉煤气化高一氧化碳制合成氨变换装置,设计采用一级等温变换炉控制变换温度,二级绝热变换炉来副产过热蒸汽,三级等温变换炉尽可能降低温度,达到深度变换的要求。该工艺不仅使高浓度的一氧化碳变换反应在较温和的工艺条件下进行,而且能副产高品质中压过热蒸汽。

关键词:粉煤气化;CO变换;等温工艺;过热蒸汽

doi:10.3969/j.issn.1004-8901.2024.06.014

中图分类号:TQ545

文献标识码:B

文章编号:1004-8901(2024)06-0050-03

Research on the Design of Combined CO Shift Process for Ammonia Production in Pulverized Coal Gasification

SHI Yu, DAI Feng-yu, ZHENG Zhi-zhong

(Hunan Anchun High-tech Co., Ltd., Changsha Hunan 410205, China)

Abstract:

Aiming at the CO shift unit of high concentration carbon monoxide to synthetic ammonia in pulverized coal gasification, a first-stage isothermal converter is designed to control the conversion temperature, a second-stage adiabatic converter to by-produce superheated steam, and a third-stage isothermal converter to reduce the temperature as much as possible to meet the requirement of deep conversion. The process not only makes the high concentration CO shift reaction occur under mild process conditions, but also can by-produce high quality superheated steam.

Keywords:

pulverized coal gasification; CO shift; isothermal process; superheated steam

doi:10.3969/j.issn.1004-8901.2024.06.014

粉煤加压气化技术配套制合成氨的变换工艺主要有多段绝热变换工艺和两段等温变换工艺,耐硫变换催化剂使用温度一般要求≤450 ℃,采用多段绝热变换工艺,一级变换炉由于反应推动力太大,热点温度难以控制,容易超温,有不少工厂实际运行温度达到470~480 ℃,设备存在风险的同时,也严重影响催化剂使用寿命。(剩余2383字)