油菜籽低温干燥模拟及响应面参数优化

打开文本图片集

中图分类号:S226.6 文献标志码:A DOI:10.13338/j.issn.1674-649x.2025.03.016

Simulation of low-temperature drying of rapeseed and optimization of response surface parameters

HU Jiulin1 ,HE Yumin1 ,FANG Qihang1 ,SHI Qianjun² ,SHI Decai² ,DONG Yude 1 (1.School of Mechanical Engineering,Hefei University of Technology,Hefei 230o09,China 2.Quanjiao Jinzhu Mechanical Manufacturing Co.Ltd.,Chuzhou 2395oo,Anhui,China)

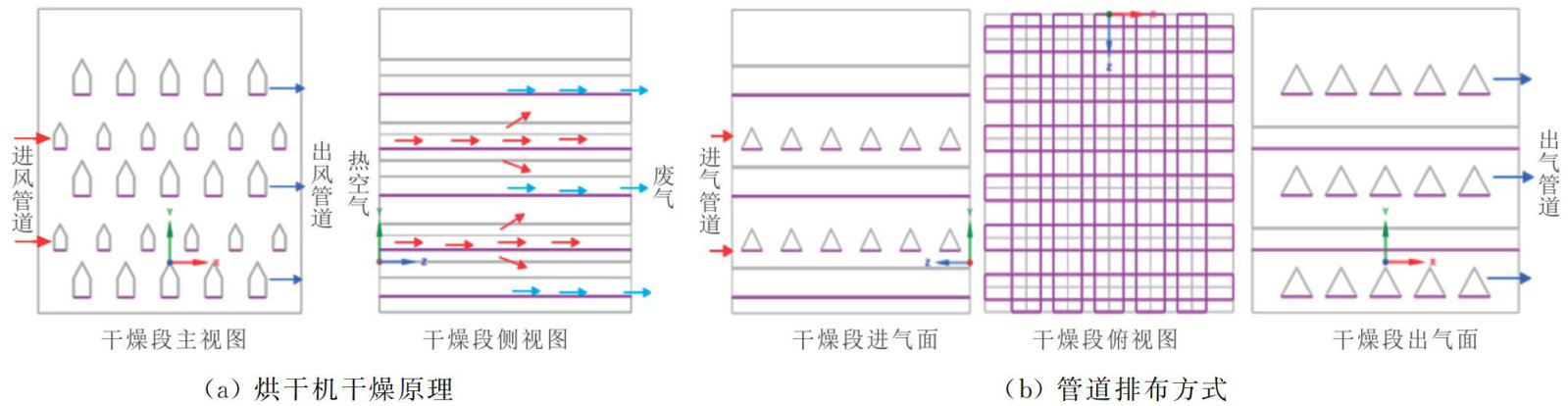

AbstractAt present,the temperature and moisture content changes in the process of low-temperature cyclic drying of rapeseed are complicated, resulting in the problem of uneven heating of part of rapeseed, large gap in moisture content and poor quality after drying.In view of this,a non-thermal equilibrium heat and mass transfer mathematical model for rapeseed was established,and the low-temperature drying process of rapeseed dryer was simulated by Fluent, and response surface analysis was used to design the simulation test,and the optimized pipeline structure and drying parameters were designed to improve the drying effect. The results show that the delta duct reduces the wind speed inhomogeneity coefficient from 23.82% to 11.99% and increases the average velocity from 0.078m⋅s-1 to 0.101m⋅s-1 compared to the ridge duct under the condition of consistent fan flow. The extreme difference of pipeline "cross" staggered arrangement is 3.28∘C ,the standard deviation is O.527 9,and the temperature unevenness coefficient is 1.80% ,basically realizing the uniform heating of rapeseed. In the pre-low temperature drying stage of the rapeseed dryer, the hot air velocity of 6.279m⋅s-1 ,hot air temperature of 58.511∘C and the triangular duct with a top angle of 88.503∘ are more favorable for the warming and uniformity of the rapeseed layer.

Keywordslow-temperature drying;rapeseed; numerical simulation; Fluent; response surface a-nalysis(RSA)

0引言

菜籽油作为中国第二大产量的植物食用油,也是食用油的重要组成部分。(剩余14848字)