基于CFD-DEM的盘式气流磨分级数值模拟

打开文本图片集

中图分类号:TB44 文献标志码:A 文章编号:2097-3853(2025)04-0382-07

Numerical simulation of classification in a spiral jet mill based on CFD-DEM

CHEN Jianxuan1’²,LI Zhanfu1,², GAO Zisheng³,TONG Xin1,2 (1. Fujian Key Laboratory of Intelligent Processing Technology and Equipment, Fuzhou 350118,China; 2.School of Mechanical and Automotive Engineering,Fujian Universityof Technology,Fuzhou 350118,China; 3.Fujian Golden Dragon Rare-Earth Co.,Ltd.,Longyan 364OOO,China)

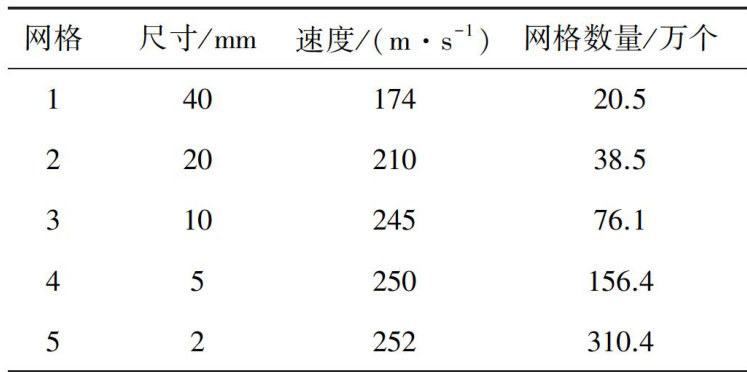

Abstract:Inorder to explore the intrinsic mechanism of iron-based powder classification ina spiral jetmill,a gassolid two-phase flow model using CFD-DEM is developed to realize the numerical simulation of spiral jet mil classification and to analyze the effect of diferent nozle inlet pressures on the clasification performance.A two-way coupled numerical simulation method of computational fluid dynamics (CFD)and discrete element method (DEM) is adopted to verify the influenceof the numberof gridson the calculation results using the nozzle inlet velocity.The interiorof thechamber can be divided into thecrushing zone,theclasifying zone and the interior of the classification wheel.Thecollision between particles mainlyoccurs inthe crushing zone,and the collsion is more intense with the increase of time,and there is almost no collision between particles inside the classification wheel. With the increase of nozzle inlet pressure,the classification efficiency decreases from 91.0% to 56.8% ,and the overall change is large. The classification accuracy shows an increasing trend from O.63 to 0.87.

Keywords: iron-based powder;spiral jet mill; computational fluid dynamics;discrete element method; airflow classification

铁基制品是粉末冶金行业生产量最大的一类材料,在一定程度上代表一个国家粉末冶金技术水平[1]。(剩余6281字)