粘合剂对聚合物复合预浸料热压罐成型的影响及工艺参数研究

打开文本图片集

摘要:介绍了真空下玻璃纤维热压罐成型过程中,从不同预浸料层数的样品中去除多余粘合剂的研究结果。通过一系列实验研究已经证实在计算过量粘合剂时,必须考虑其黏度和适用期以及填料的厚度和渗透性,这取决于所施加的热压罐加压成型的压力值。

关键词:高压成型;玻璃纤维;聚合物粘合剂;填料渗透性

中图分类号:TQ343+.1;TQ433.4+3 文献标志码:A 文章编号:1001-5922(2023)03-0094-04

Research on the influence and process parameters of polymer composite parts on autoclave molding

YUE Ming,HONG Xiaoming,ZHANG Zeliang

(AVIC Xi ’an Aircraft Industry Group Company LTD.,Xi ’an 710000,China)

Abstract: This paper introduces the research results of removing excess adhesive from samples with different pre- preg layers in the process of glass fiber autoclave molding under vacuum. It has been confirmed through a series of experimental studies that when calculating the excess adhesive,its viscosity and service life,as well as the thick- ness and permeability of the filler must be considered,depending on applied autoclave pressure value.

Keywords: autoclave molding;prepregs;fiberglass;polymer binders;VSO-200M binder;filler permeability

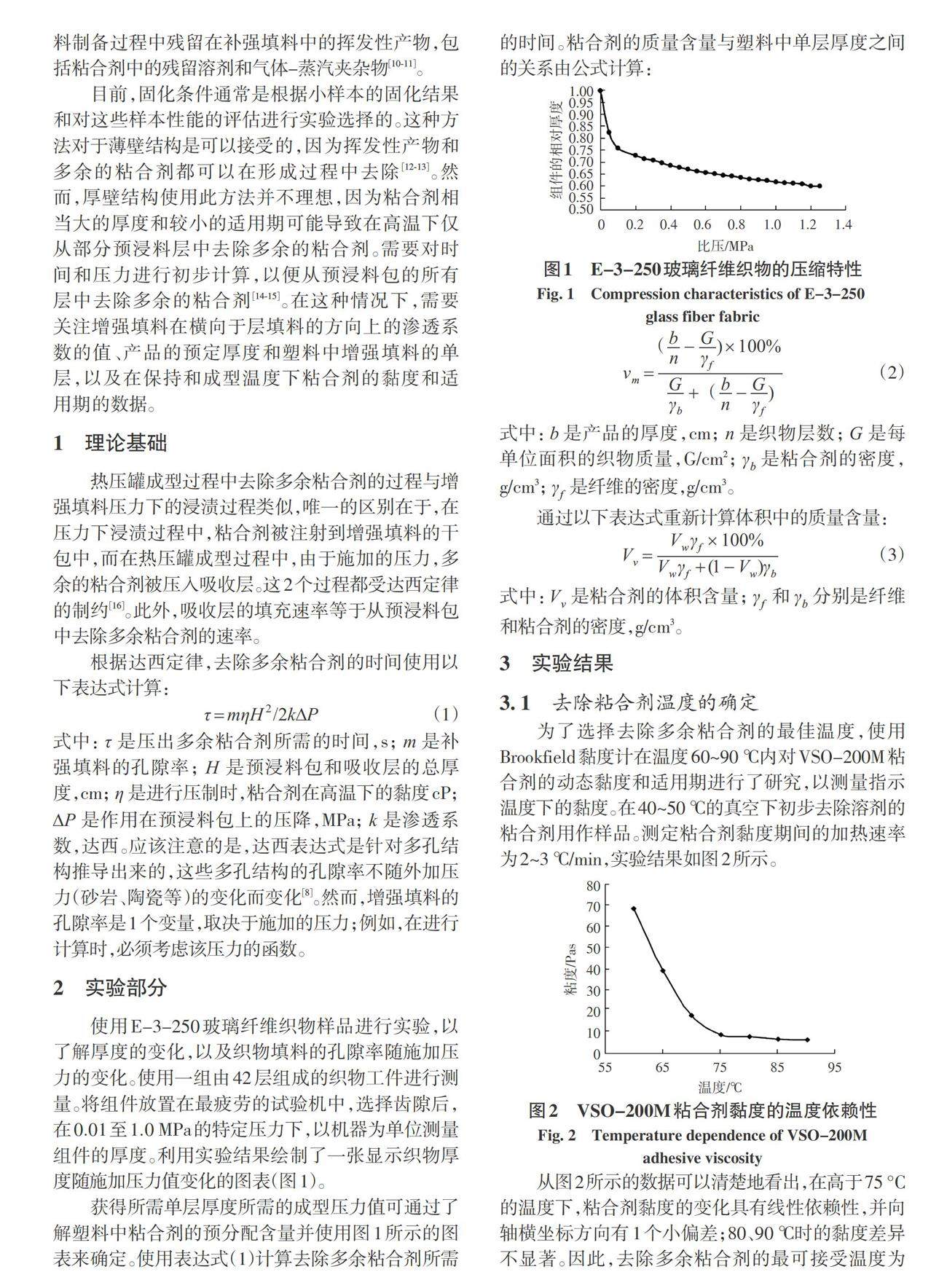

聚合物复合材料(PCMs)在包括航空工业在内的各个技术分支中的应用越来越广泛。(剩余6046字)