双注意力机制下的钢材缺陷检测方法

打开文本图片集

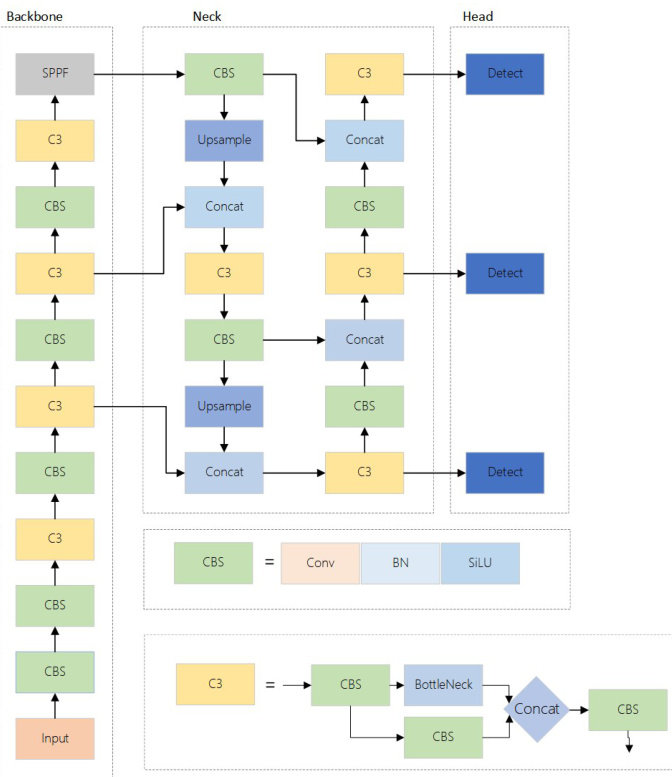

【Abstract】Toaddressthe problems of missed detection,false detectionand low detection accuracyin thedetectionof steel surfacedefects,adual-atentionmechanismbasedonYOLOv5 isproposed todetectsteeldefects.Firstly,toaress thedefects onthestelsurfacethatare similar tothe backgroundandprone to misseddetection,aBRAmodule isadded to the backbone network,theBRAC3 moduleisdesigned,andanovelandeficientchannelatention mechanism,SECAisintroduced.Thedualatentionmechanismenhances thesemantic informationof steeldefectsand increasesatentiontomportantpixels;secondly,thecross-scalebidirectionalfeature fusionnetwork isusedtofurther integratefeature information from shallowand dep networks tocapture more feature details;finally,anew lossfunction,SMPDIoU,isdesignedbycombining the ideasof SIoUand MPDIoU,which makesthealgorithm fasterand further improvingthe detectionaccuracy.Experimentalresults showthattheimproved model improvesthe mAPby5.1 percent,theregresionrate by3.5 percentand the FPS value by 21.4f/s ,compared with the classical YOLOv5 model. While improving detection accuracy, the detection speed is also enhanced, demonstrating its application value in industrial production.

Key words】YOLOv5; defect detection; attention mechanism; BiFPN; MPDIoU

[中图分类号〕TP391.4 [文献标识码]A [文章编号]1674-3229(2025)01-0110-10

0 引言

其在制造的过程中,容易产生表面缺陷,而表面缺陷会降低钢材的强度,缩短钢材的使用寿命,影响其质量。(剩余8384字)