特高压井口节流阀节流性能及结构分析

打开文本图片集

中图分类号:TE931 文献标识码:A DOI:10.12473/CPM.202407066

Zhou Tianming,He Qiang,Wang Junyu,et al.Throtling performance and structural analysis of UHP wellhead throttle valve[J].China PetroleumMachinery,2025,53(7):75-82.

Throttling Performance and Structural AnalysisofUHP WellheadThrottleValve

Zhou Tianming1.²He Qiang1Wang Junyu³Dai Qiping1.2Han Chuanjun' (1.MOEKeyLaboratoryforOilandGasEquipmentatSouthwestPetroleumUniversity;2.CNPCBaoj OilfieldMachineryCo., Ltd.;3.CCDCDownhole Service Company)

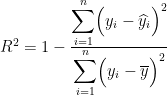

Abstract:The throtle valve,,as an ultra-high pressure (UHP)wellhead device,is susceptible to erosion failure.This paper proposes thedesigns of spool and anti-sprint protection sleeve for double-wedge throttle valve,and analyzes theflow field characteristics of nine spools of the double-wedge throtle valve at diferent openings.The results show thatthespools ofthedouble-wedgethrotle valvearebetter-performed in erosionresistance than thatof the single-wedge throtle valve.With the increaseof spool stroke,the velocityof drillingfluid passing throughthe wedge-shapedsurfaceofthespol increases,andthedrillingfluid hasa strong erosion to the spooland the wall surfacebelow thespol.Among the9types of spoolsof the double-wedge throttle valve,the convex symmetrical spool has the best throtling and anti-erosion performance,and its linear regression coeffcientof pressure drop curve is 99. 6% . The cavity size has a significant impact on the performance of the throtle valve:expansion of the cavity size by 30 mm leads to a decrease of maximum velocity by 3.87% on average.After the spool anti-sprint protection sleeve is installed,the maximum fluid velocity decreasesby an average of 30. 35% ,extending the service life of the spool.The research results provide areference forthe design and application of UHP wellhead throtle valves.

Keywords: UHP wellhead; wedge throtle valve;double-wedge surface; erosion and wear; design optimization

0 引言

节流阀是石油和天然气钻采过程中使用的关键装置之一,其主要作用是控制井口流体的流量和压力,以确保钻井或油气生产过程的安全。(剩余10233字)