EIP钢筋锈蚀量监测装置的设计与误差校正

打开文本图片集

中图分类号:TU528.01

文献标识码:A

Design and Error Correction of EIP Steel Bar Corrosion Monitoring Device

WANG Hui 1 , TIAN Li 1 , XU Zhetao²,DU Zhenxing’,SUN Xiaoguang³,WANG Penggang 1* (1. Department of Civil Engineering, Qingdao University of Technology, Qingdao, Shandong 26652O,China; 2.Shandong Construction Engineering Quality Inspectionand Testing Center Co.,Ltd.,Jinan,Shandong 2501oo,China; 3.Shandong Chambroad Eco-friendly Materials Co.,Ltd.,Binzhou,Shandong 2565OO,China)

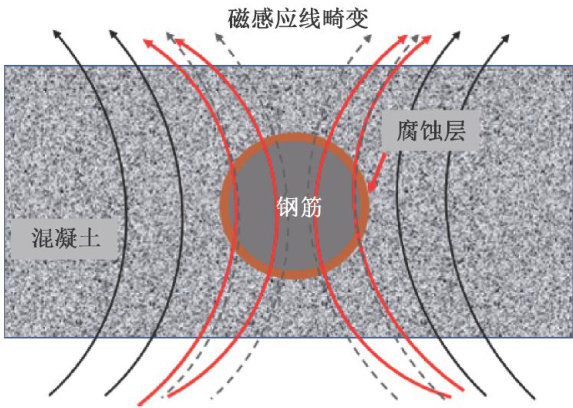

Abstract: In order to study the problems of large errors and difficulty in quantification when using electromagnetic methods to detect steel corrosion, this paper developed a set of steel corrosion monitoring device based on the principle of electromagnetic induction by utilizing the difference in magnetic permeability between the steel bars and their corrosion products. This monitoring device uses permanent magnets to provide a closed magnetic field,transmits the magnetic field using silicon steel sheets,and embeds Hall elements at both ends of the silicon steel sheets to sense the changes in magnetic permeability caused by steel corosion.Through calibration,a correction formula for the theoretical calculated corrosion rate of the internal steel bars in concrete and the actual corrosion rate was obtained based on Faraday's formula. The maximum error between the corrosion amount of the steel bars calculated by this correction formula and the actual corrosion amount measured by the weight loss method was 1.044% : Through the concrete internal sensor test,an accurate relationship between the corrosion amount of the steel bars and the change in Hall voltage was obtained based on the linear regression model,providing a scientific method for the durability monitoring of reinforced concrete structures.

Key words: nondestructive testing;corrosion rate; Faraday’s law;magnetic permeability

钢筋的锈蚀程度是影响混凝土结构耐久性的关键因素,也是判定混凝土结构剩余寿命的重要依据[1-3]。(剩余8431字)