融合三重注意力机制的板材焊缝缺陷在线检测

打开文本图片集

Online detection of plate weld defects incorporating triple attentionmechanism

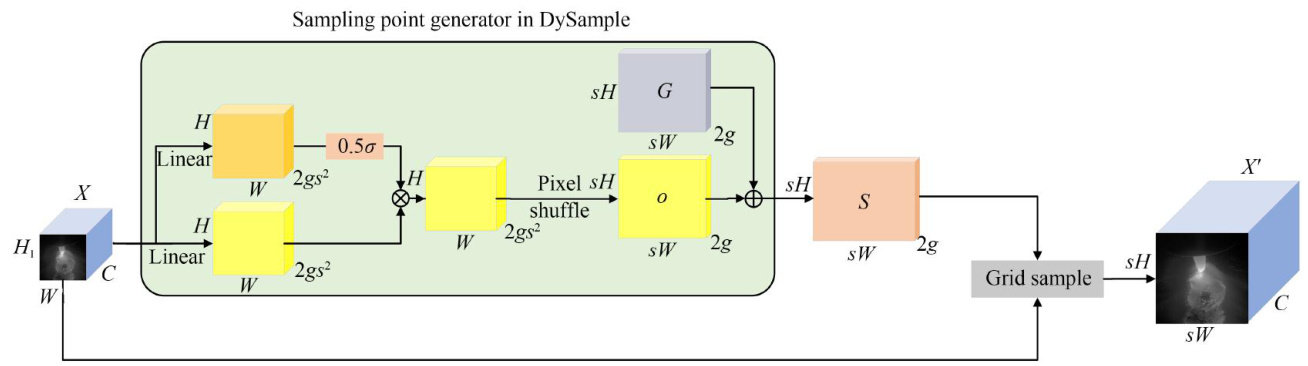

Abstract: Existing weld defect detection algorithms exhibit limitations such as inaccurate detection of smal-scale defects,suboptimal real-time performance,and excessive parameter counts. To overcome these challenges,a novel online detection algorithm,termed YOLO-TR,has been developed for the identification of five prevalent weld defects:burnt-on,burn-through,slag entrapment,unfused joints,and misalignment. The YOLO-TR algorithm integrates a Triplet Attention mechanism within the YOLOv5 feature extraction network to enhance feature representation. The neck network employs a dynamic upsampling (DySample) module,replacing the original up-sampling component of YOLOv5, thereby im proving feature map resolution to satisfy high-precision inspection requirements. The incorporation of a distributed focus detection head (CLLAHead) augments robustness to scale variations while concurrently reducing the model's parameter count.Furthermore,the original YOLOv5 loss function is substituted with the Shape-IoU loss function to enhance regression accuracy and accelerate convergence. The effectiveness of the proposed algorithm is validated through ablation and comparative experiments. Ablation results demonstrate that the YOLO-TR model achieves a precision of 92.5% (an increase of 3.6% ),a recall of (204号 88.8% (an increase of 2.1% ),and an average precision (mAP@0.5) ) improvement of 0.8% ,with only a 4.4% increase in parameter count. The proposed algorithm delivers high eficiency and accuracy in online weld defect detection,exhibiting strong robustness and generalization capabilities,thereby substantiating its efficacy in industrial defect detection applications.

Key Words:detection defect;YOLOv5;triple attention mechanism;distributed focus detection head; DySample

1引言

焊接作为工业生产的重要工艺,广泛应用于航空航天、汽车制造、船舶、农业装备和传感器技术等领域。(剩余15703字)