基于双特征槽工件的旋转轴几何误差辨识

打开文本图片集

Geometric error identification of rotary axes based on dual-feature grooved workpiece

ZHANG Ao1,XIANG Sitongl*, YANG Jianguo² (1.Faculty ofMechanical Engineering and Mechanics,Ningbo University,Ningbo , China; 2.Faculty ofMechanical Engineering,Shanghai Jiao Tong University,Shanghai 2OO24O,China) * Corresponding author, E-mail: xiangsitong@nbu. edu. cn

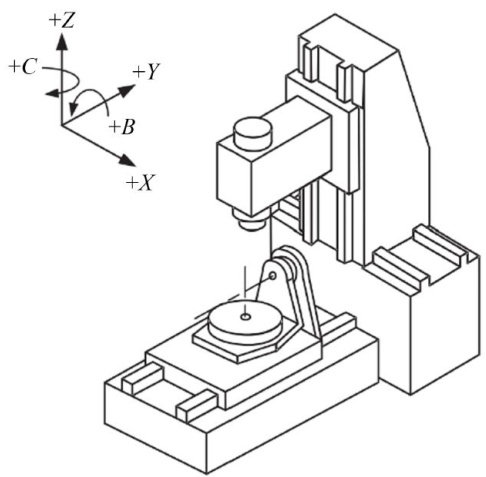

Abstract: A method for identifying position-dependent geometric errors (PDGEs)of rotary axes in fiveaxis machine tools is proposed, employing dual-feature grooves.This approach entails machining two distinct types of feature grooves on a cubic workpiece and implementing four measurement modes to facilitate high-precision identification of rotary axis geometric errors. Unlike conventional feature workpieces,the proposed design does not impose stringent requirements on groove depth and length,thereby substantially reducing material removal while mitigating the effects of cutting forces,thermal deformation,and linear axis errors on measurement outcomes.Furthermore,the identification model is designed to amplify the influence of angular eror motions,diminishing the impact of measurement uncertainty on identification accuracy and enhancing result reliability. Comparative experiments with the T-block identification method confirm the method’s accuracy,demonstrating a maximum deviation of 2.7μm for displacement error identification and -2.3" for angular error identification,with an average consistency of 93.6% between the two methods.

Key words: five-axis machine tool;rotary axis;geometric error;error identification; feature-embedded workpiece;on machine measurement

1引言

五轴机床广泛应用于航空航天、汽车等领域的复杂曲面零件加工[1-2]。(剩余14574字)