矫直工艺对探伤合格率影响研究

打开文本图片集

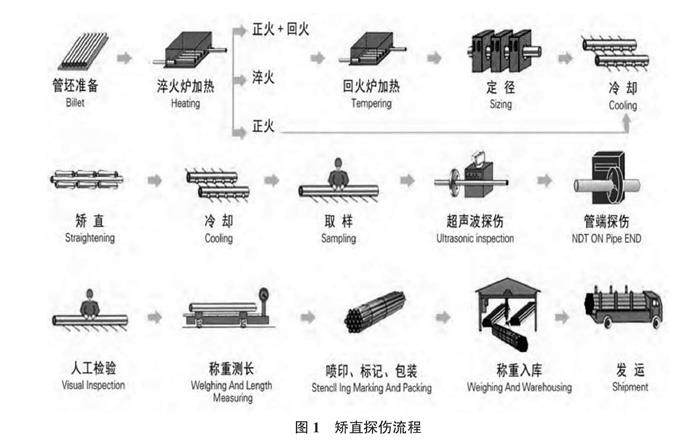

摘 要:探讨矫直工艺对探伤合格率的影响,通过对矫直原理、设备和技术的介绍,结合探伤技术的基本原理及其在矫直过程中的应用,分析了矫直过程中可能产生的缺陷类型及其对探伤结果的影响。通过试验设计与数据分析,验证不同矫直参数对材料探伤性能的影响,并提出优化矫直工艺以提高探伤合格率的具体建议。

关键词:矫直工艺;探伤技术;合格率;缺陷;试验分析

STUDY ON THE INFLUENCE OF STRAIGHTENING PROCESS ON THE QUALIFIED RATE OF FLAW DETECTION

Chen Chen

(Nanjing Iron and Steel Co., Ltd. Nanjing 210035,China)

Abstract:The paper discusses the influence of straightening process on the qualified rate of flaw detection. Through the introduction of the straightening principle, equipment and technology, combined with the basic principles of the flaw detection technology and its application in the straightening process, the type of possible defect and its influence on the flaw detection results are analyzed. Through experimental design and data analysis, the influence of different straightening parameters on the flaw performance of the material is verified, and some specific suggestions to optimize the straightening process to improve the qualified rate of flaw detection.

Key words: straightening process; flaw detection technology; qualified rate; defect; experimental analysis

0 引 言

在现代冶金工业中,矫直工艺对于保证钢材产品的几何尺寸精度和表面质量至关重要,但矫直过程中可能会产生一些微观或宏观的缺陷,这些缺陷不仅影响产品的最终使用性能,还会对后续的探伤检测造成干扰。(剩余5316字)