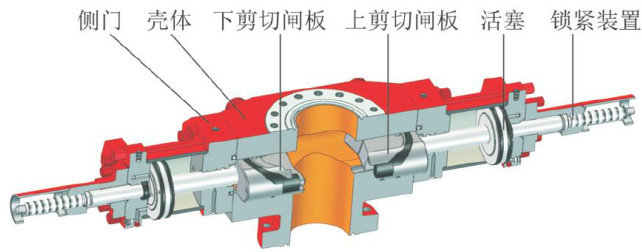

超深井剪切闸板防喷器高温密封结构优化与试验

打开文本图片集

中图分类号:TE921 文献标志码:A 文章编号:1000-7393(2025)-04-0434-08

Abstract:Against thedemandinghigh-temperatureandhigh-pressre (HTHP)conditions inultra-deepwelsforshearramblowout preventer (BOP),thisstudyivestigatesthe high-temperaturesealing mechanismandstrategiesforenhancingthesealintegrityof shearram.Utilingacombinedproachofteoreticalanalysis,fiteelementsimulation,andexpeimentalvalidationonanFZ35- 105BOPtest,teeseachexamiesthifuenceofhdrogenatednitrilebr(HBR)materialproperti,thsuctualdesinof theshearbladesealandsideseals,andtheram blockconfigurationonhigh-temperaturesealing performance.Resultsdemonstrate thatHNBRistheoptimalsealingmaterialfordrilingwellcontrolquipment inHHevironmentsduetoitssuperiorhermal stability and chemical resistance.Under extreme conditions of 177°C and 105MPa ,an end-face sealing shear structure maintained effective sealing for 493 minutes. This represents a 17.1% improvement over the 42l minutes achieved by traditional contact sealing and far exceeds the standard requirement of 6O minutes.When the single-sidecompression of the side seal reaches 5.3mm ,the contact stress can achieve 105MPa ,thereby achieving zero leakage under wellbore pressure.An interlocking shear ram design reduced the clearance between the upper and lower rams by 40%50% ,effectively mitigating seal extrusion. A quantitative model correlatingsidesalompressiontoalingprsueastablshd,withpdictiosdeviatigfroexperimentaldatabsthan 10% .Thestudyrecommends prioritizing end-face sealing shear structuresfor large-bore BOP.These findings providecritical technicalsupportforthe designand manufactureofshearram BOPcapableofoperating in the HTHPenvironmentsencountered in ultra-deep driling, significantly enhancing their sealing performance and high-temperature resistance.

Key words:ultra-deepwell high temperatureand pressure;shearram;sealingperformance;high temperatureresistance

0 引言

近年来,随着全球油气勘探理论、技术与装备的不断突破,深层/超深层油气资源的勘探开发呈现加速发展态势[1]。(剩余14804字)