车身密封胶胶泡的成因及对策

打开文本图片集

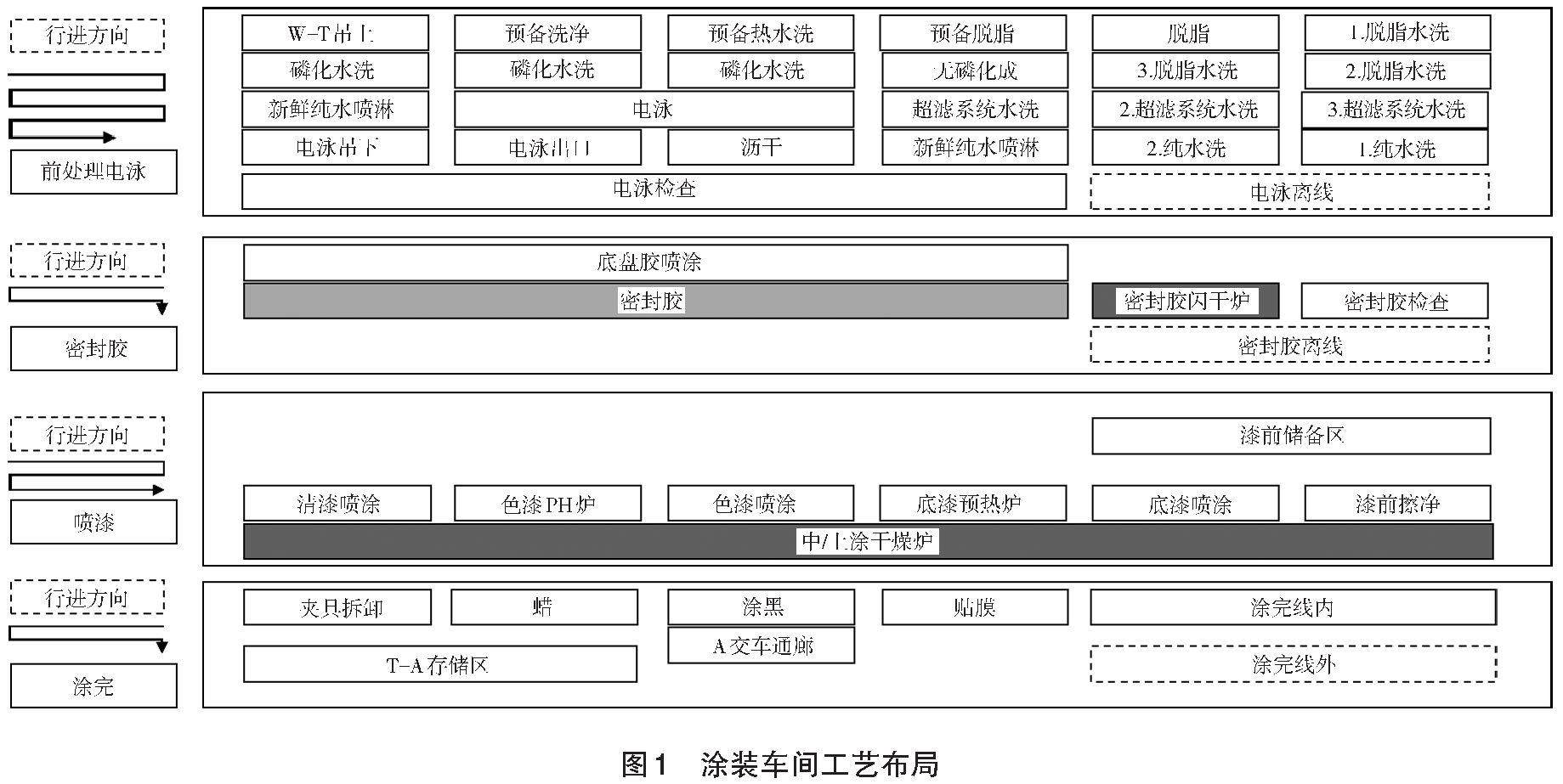

摘要:为解决车身焊缝密封胶胶泡问题,从密封胶胶泡的发生原因作为切入点、首先详细介绍了车身解体、断面分析的密封胶胶泡分析方法,明确发生原因为折边胶胶量过大,采用调整板缝、调整折边胶等处理方式来解决问题,结果表明:板缝≤0.02 mm时可以消除胶泡,调整炉温可减小胶泡的尺寸,无法改善胶泡数量。

关键词:密封胶 密封胶胶泡 胶泡分析方法 胶泡解决方法

中图分类号:U466 文献标识码:B DOI: 10.19710/J.cnki.1003-8817.20230205

Cause and Solution of Automotive Body Sealant Bubble

Li Fu, Song Shuang

(FAW Toyota Motor Co., Ltd., Changchun 130000)

Abstract: To address the issue of automotive body weld seam sealant bubble, this paper started from the cause of automotive body sealant bubble, it firstly introduced 2 sealant bubble analysis methods including automotive body break-up analysis and section analysis, determined that excessive use of hemming sealant was the cause of sealant bubble, proposed the adjustment of slab gap and hemming sealant to eliminate sealant bubble. The results show that sealant bubble will be eliminated when slab gap is less than 0.02 mm, whereas adjustment of furnace temperature can only reduce the size of sealant bubble, can’t reduce the amount of sealant bubble.

Key words: Sealant, Sealant bubble, Sealant bubble analysis method, Sealant bubble solution

1 前言

中国汽车行业经过二十几年的高速发展,已经从增量市场逐步过渡到存量市场。(剩余4350字)