新能源汽车电池模组固定螺栓断裂失效分析

打开文本图片集

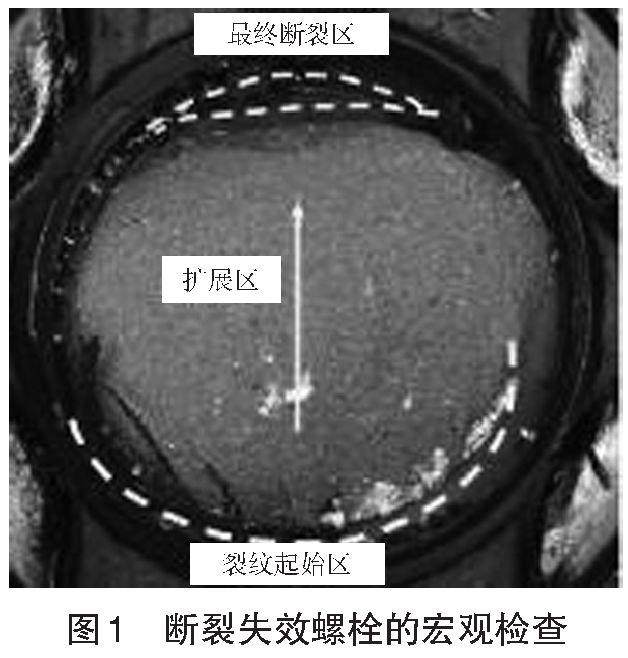

摘要:某新能源汽车电池模组固定使用的高强度螺栓在振动试验过程中发生断裂,通过理化检验、装配工艺和振动测试情况多方面对螺栓断裂失效原因进行了调查分析。调查分析结果表明,螺栓装配不当形成疲劳源,在进行Z向振动时疲劳源在交变应力和失效螺栓的上下结合面处螺栓受径向剪切力的共同作用下不断扩展,最终导致断裂。

关键词:电池模组 螺栓 疲劳断裂 装配不当

中图分类号:TG113.22 文献标识码:B DOI: 10.19710/J.cnki.1003-8817.20230207

Fracture Failure Analysis of Battery Module Fixing Bolt for New Energy Vehicle

Cao Zhonghua1, Dong Lei1, Du Qingyuan1, Yan Zhongming2

(1. ZEEKR Intelligent Technology Co., Ltd., Ningbo 315336; 2. Jiashan Huiyuan Precision Machinery Co., Ltd., Jiaxing 314112)

Abstract: The fracture of a high-strength bolt used for fixing battery module of a new energy vehicle in the process of vibration test was investigated and analyzed through physical and chemical inspection, assembly process and vibration test. The results of investigation and analysis show that the cause of fracture is the formation of fatigue source caused by improper bolt assembly, the fatigue source continues to expand under the combined action of alternating stress and radial shear force at the upper and lower joint plane of the failed bolt along Z-direction vibration, which eventually leads to fracture.

Key words: Battery module, Bolt, Fatigue fracture, Improper assembly

1 前言

在振动激励条件下,受外界循环剪切载荷作用螺栓连接状态会发生变化,不仅会影响结构的正常功能,甚至会造成严重后果。(剩余6372字)