板式定制家具生产管理系统构建实施方案研究

打开文本图片集

中图分类号:S777;F273 文献标识码:A 文章编号:2095-2953(2025)02-0080-06

Implementation Plan for Building a Production Management System for Customized Panel Furniture

ZHANG Jia-sheng1, TU Dong-dong²,QIN Jia-pan³ (1.Wuzhou Forestry Science and Technology Research Institute,Wuzhou Guangxi 543OO3,Chin: 2.Guangxi Rabbit Baby Home Furnishings Co.,Ltd,Nanning Guangxi 5302Oo,China; 3.OPPEIN Home Furnishings Group Co.,Ltd,Guangzhou Guangdong 51O450,China)

Abstract:The high degree of customization of panel furniture isan important symbolof intellgent manufacturing.At the same time,inteligent manufacturing factories are alsoan important component of achieving Industry 4.O.In the process of upgrading the production and manufacturing management system of panel furniture,in order to solve the problems of complicated business proceses,dificult production management,unclear production processes,and chaotic material sets,the combination of ERPand MES dual systems is mainly used to achieve inteligent manufacturing upgrades,and to buildan overallsystemwith material management,order management,planning management,production process management,and warehouse management as the main focus,in order to solvethe process operationof enginering from order acceptance to shipment.However,the implementation efect of the system determines thequalityof intellgentupgrades due tothe diferentconditions among enterprises,The implementation ffect of information technology upgrading is of great significance for improving the productivityand market competitiveness of panel customized furniture enterprises.

Keywords;Forestry engineering;Customized panel furniture;Inteligent manufacturing;promotionof information technology;Implementation plan

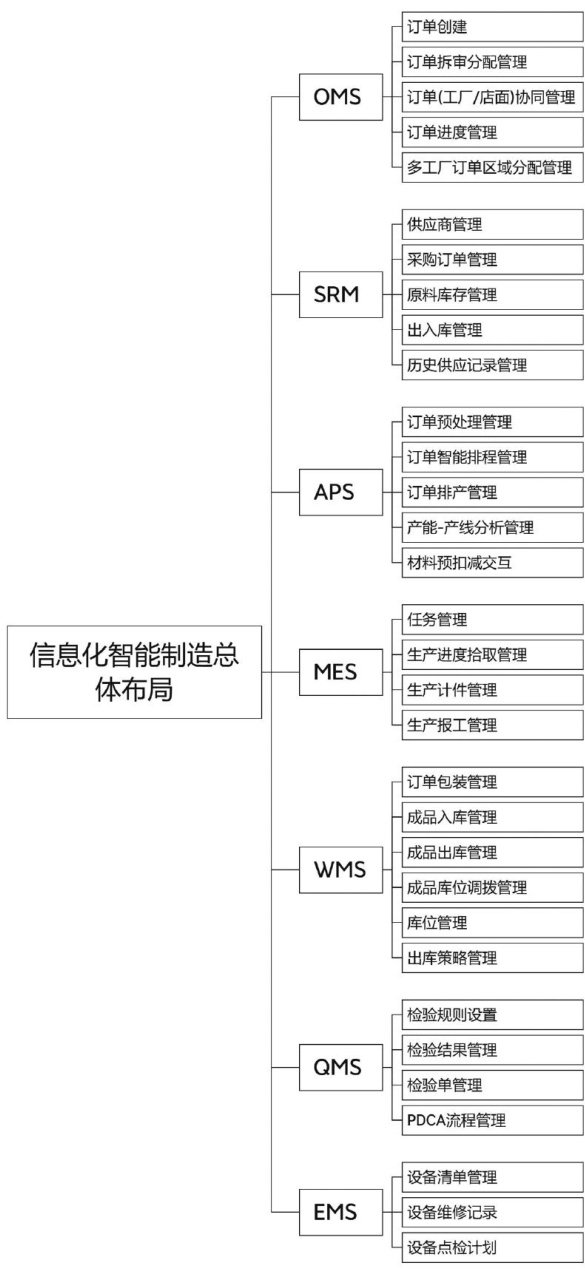

随着社会的进步以及人民对美好生活的需求不断增加,定制化需求层出不穷,特别体现在家居空间环境中,家具的选择上,不仅要满足原始空间的尺寸限制,更要满足业主对空间的利用要求及日常使用的要求,因此在板式家具的生产上也因市场要求变得更加柔性,以适用大规模的高度定制化生产,从以往的生产为主的生产导向改向市场需求为主的生产导向,高度的定制化生产,对生产管理的提出了更高的要求,我国板式定制家具从20世纪80年代末起就开始使用信息化系统,从国外引入信息化生产管理系统就是为了解决复杂的产品组合生产方案,提高生产效率,如今已经发展成了以ERP与MES相结合,ERP解决物料供给大环节,MES解决生产执行大环节为主流的结合方案,涵盖了CRM(客户管理管理)、SRM(供应链管理)、OMS(订单管理系统)、APS(高级计划与排程系统)、PCS(生产过程控制系统)、WMS(仓储管理系统)QMS(质量管理)等多模块的内容[1],改变了生产过程中的信息孤岛的问题,提高了企业的运作效率与经营质量,但不同企业因其自身的业务细分不一致,订单来源不相同及企业内部管理的特殊性等原因,在信息化制造升级的过程中,不能盲目参照某一成功企业的实施经验生搬硬套,否则只能适得其反,在企业进行信息化建设时往往要针对企业现状进行信息化智能制造升级的范围,内容及关键技术实现进行选择,构建适合企业自身的信息化平台,才能让升级是真实基于企业现状去实现的,让信息化智能制造的升级能在生产企业内部顺利落地,发挥价值。(剩余5875字)