基于旋向的薄煤层采煤机滚筒装煤工艺及性能优化

打开文本图片集

关键词:薄煤层;螺旋滚筒;离散元仿真;装煤性能

中图分类号:TD421.6 文献标志码:A 文章编号:1672-9315(2025)05-0925-16

DOI:10. 13800/j. cnki. xakjdxxb.2025.0509

Optimization of coal loading process and performance of thin coal seam shearer drum based on rotational direction

HE Longlong',CAI Haoqian1,WU Yue¹,CHEN Hua’,SUN Lianwei¹, LI Jiale¹,YU Zheqi1,BAI Qi2 , CAO Xiangang1, ZHANG Xuhui1 (1.CollegeofMechanical Engineering,Xi'an UniversityofScienceand TechnologyXi'an71Oo54,China; 2.Shaanxi XiaobaodangMining Co.,Ltd.,Yulin719302,China)

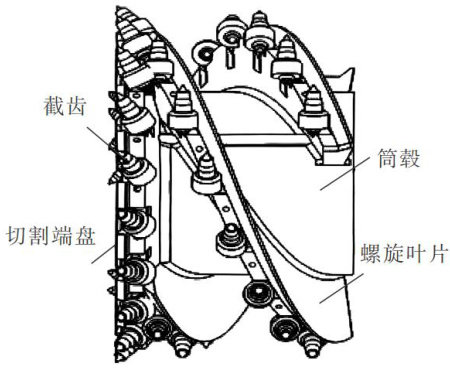

Abstract: In order to solve the problem of poor coal-loading effciency of thin coal seam mining machine drums in narrow coal passage spaces,a rotation-based thin coal seam mining machine drum coal loading process and performance optimization method is proposed.By systematically analyzing the key factors influencing the coal loading process and performance of thin coal seam mining machine drums, a coal wall discrete element model similar to actual coal wall conditions was established using discrete element simulation technology to simulate the interaction between coal blocks and the coal wall during cuting.Further optimization analysis of key parameters,such as drum rotation direction,spiral pitch angle,cutting depth,drum speed,and traction speed was conducted by single-factor analysis and orthogonal experiment methods.The results were validated by testing the coal loading process of the actual coal cutter( MG2×200/920 ) drum( ϕ1 250 mm) at the 141O working face of a thin coal seam in a certain coal mine.The results showed that when an inward-rotating drum was used in combination with a 20∘ screw pitch angle and a traction speed of 7m/min ,the coal flow characteristics were significantly improved,and the coal loading efficiency was increased to 73.6% . The optimized inward-rotating drum enhanced the coal block ejection fect,reduced coal block blockage below the swing arm,and effectively solved the problem of limited coal loading space in thin coal seams.The research results provide experimental validation for the drum structure and cutting technology in actual operating conditions, enhance the adaptability and operational eficiency of coal mining machine drums in thin coal seam environments,and offer technical support for improving coal loading efficiency and conserving coal resources.

Key words: thin coal seam; spiral drum; discrete element simulation; coal-loading performance

0 引言

随着绿色开采理念的普及,如何提高煤炭的回采率并减少采煤过程中的环境污染问题变得愈发重要[1]。(剩余17881字)