基于视觉检测的胶合板表面缺陷修补设备的设计与实现

打开文本图片集

中图分类号:S777;TS64 文献标识码:A DOI:10.7525/j.issn.1006-8023.2025.04.020

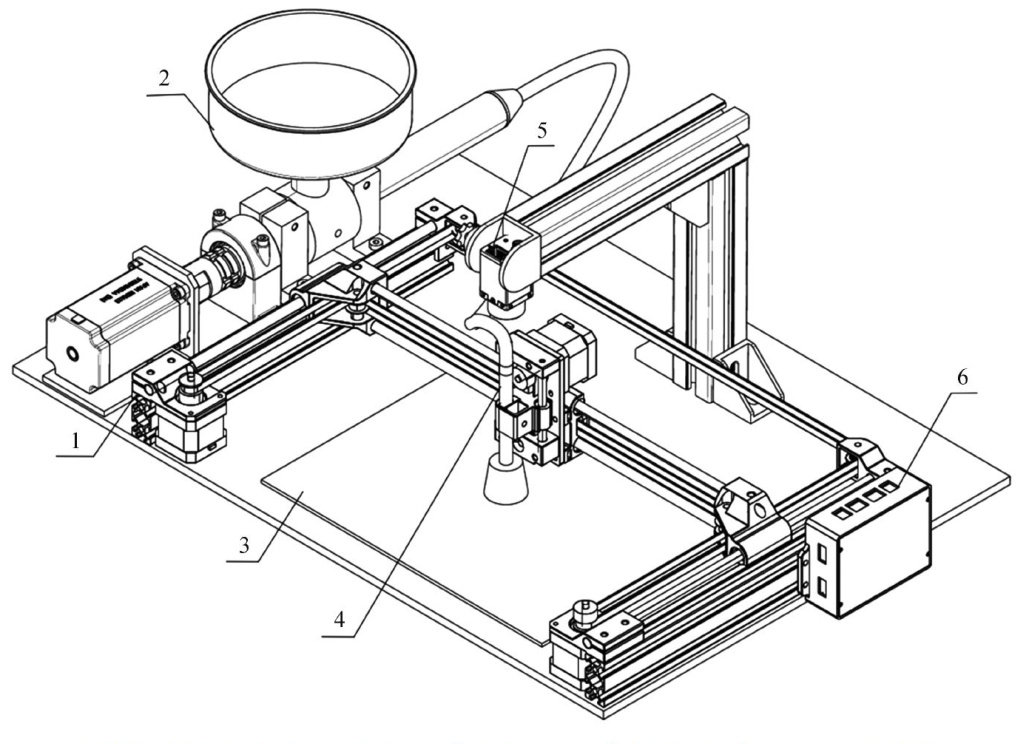

Abstract:To solvethe problemsoflow eficiency,highlaborintensity,andpoor working environment in plywood production,a surface defect repair equipment for plywood based on visualdetection and automation controltechnology to improve the surface qualityand production eficiencyof plywood wasdesigned.Theequipment mainlyincludeda visual detection and intellgent control system,a positioning system,an extrusion system,andarepairing mechanism.The visual detectionand intellgentcontrolsystem identifiedthesizeand positionof defects through visualdetection technologyand generated coresponding G-code instructions (the most widely used CNC programming language forcomputer numerical control machines),which were transmited to the positioning systemand extrusion system.The positioning system used the CoreXY mechanism(dual motordrive(Motors M1and M2),timing belt drive,X-shaped structure),andthe system received the instructions and controls therepairing mechanism to determine the defectrepair pointthrough thecoordination of M1,M2,and Z motors.The putyextrusion machineof the extrusion system was used to realize stable extrusion andevencoverage of theputtyatthedefectsite.The testshowed thatthe detection accuracyof theequipmentfor holes, cracks and other defects reached 97. 1% and 70.6% respectively,which can effectively cover the surface defects of the plywood andavoid large areas of coating.The repaired plywood issuperiorto manual repairin termsof putty residue, usage and repair time,providing an efective solution forthe automatic repairof the plywood processing industry.

Keywords: Plywood; surface defect repair; CoreXY mechanism;repair equipment;machine vision

0 引言

胶合板生产属于木材深加工领域,通过旋切将原木加工成单板,随后单板历经干燥、拼接、涂胶、组坏、预压、热压、腻补、裁边以及砂光等一系列工艺,最终制造成板材[1-3]。(剩余13858字)