基于3D打印技术对模具冷却系统的优化

打开文本图片集

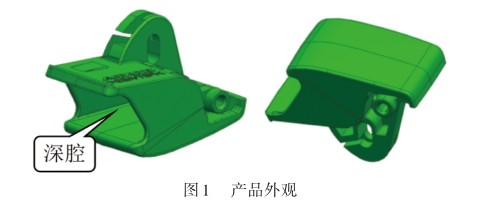

摘要:塑料模具冷却系统对整个成型周期有重要的作用。主要通过Moldex3D模流分析软件、结合3D打印技术,以深腔塑料件为研究对象,模拟传统水路和随形水路的冷却效果,从而评估以3D打印技术为基础的随形水路方案对注塑成型周期的优化作用。

关键词:模流分析;3D打印技术;随形水路

中图分类号:TS943.66文献标志码:A文章编号:1009-9492 ( 2022 ) S1-0035-02

Optimization of Mold Cooling System Based on 3D Printing Technology

Xie Bixin

(Shantou Ruixiang Mold Co., Ltd, Shantou, Guangdong 515041, China)

Abstract: The cooling system of plastic mold plays an important role in the whole molding cycle. Moldex 3D mold flow analysis software, combined with 3D printing technology, is mainly used to simulate the cooling effect of traditional waterways and conformal waterways with deep cavity plastic parts as the research object, so as to evaluate the optimization effect of conformal waterways based on 3D printing technology on the injection molding cycle.

Key words: model flow analysis; 3D printing technology; c onformal waterway

0引言

注塑成型工艺流程主要包括:塑化-合模-注射-保压-冷却定型-开模取出制品等过程;其中,冷却时间占整个成型周期约2/3以上,因此,合理的冷却系统可以缩减成型周期,使产品温度均匀从而减小变形,进一步提高注塑生产效率和产品质量,降低生产成本[1]。(剩余1876字)