超低温用高锰奥氏体钢熔池凝固行为及特征

打开文本图片集

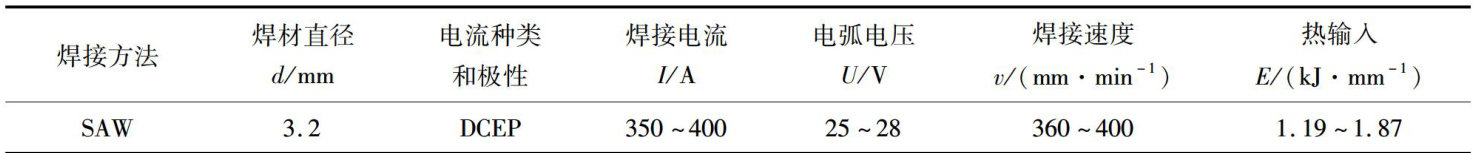

Abstract: weld metal high manganese austenitic steel was prepared by submerged arc welding process with the main composition (wt. % ) range 0.30 -0.50 C,22.00 -25.00 Mn,3.50 -5.50 Cr. segregation behavior aloying elements thesolidificationcharacteristics themolten pool high manganese austenitic steel were studied by OM,EBSD,EPMA other analysis methods. analysis microstructure chemical composition shows that there are inhomogeneous mixed zone partially melted zone (PMZ)in thefusion zone high manganese austenitic steel welded joints prepared with the same composition system. ally elementsegregation zoneC,MnCr produced byhotrolling in the teststeelresulted inpartial melting the PMZ in the fusion zone the welded joint, further increases its degree elemental segregation. inhomogeneous mixed zone co-crystalizes in the PMZ in the m cellular crystals, the distribution theall elementscontinues thedistribution inthePMZ. molten pool co-crystallzesinthe mcellular crystals on the protruding solid phase peninsula on the PMZ. width the initial cytosolic crystals correlates is intrinsically related to the spacing the hot-rolledsegregation bs thebase metal,which is produced by thesegregation alloying elements in the hot rolled strip in the partially melted zone theconcave solidliquid interface med by its partial melting.

words: high manganese austenitic steel; partially melted zone;solidification crystallzation;segregation

0 前言

随着清洁能源液化天然气(liquefiednatural gas,LNG)的迅猛发展,超低温用高锰奥氏体钢成为研究热点[1-4],通过添加含量为 22.5%~25.5% (质量分数)的Mn元素和含量为 0.40% (质量分数)左右的C元素,以及 Cr 和Cu等合金元素,控制其层错能(stackingfaulten-ergy,SFE)在 20~24mJ/m2 的范围内,促进孪生诱导塑性(twinninginducedplasticity,TWIP)效应,使其具有优良的综合力学性能,特别是优异的超低温冲击韧性[5-7]。(剩余9184字)