选区激光熔化成形GH3536拉伸力学性能分析

打开文本图片集

中图分类号:TG333. 17 文献标识码:A

Abstract: Utilizing Selective Laser Melting (SLM) technology, the GH3536 alloy specimens for tensile tests were fabricated by selective laser melting technology. The differences in tensile mechanical properties under different forming angles were tested. After the horizontal formed specimens were subjected to hot isostatic pressing treatment (1 175 ℃ , 160MPa , and 1h furnace cooling), the specimens without treatment (i. e. , deposited state specimens) were compared. The reasons for the changes in material properties after the treatment were analyzed. The tensile curves of GH3536 alloy with randomly distributed crystal orientations were calculated by the crystal plasticity finite element method. Combined with the VRH averaging method for the estimation results of elastic modulus, it was found that the material properties after hot isostatic pressing treatment were close to isotropic.

Key words: selective laser melting; GH3536; tensile mechanical property; crystal plasticity

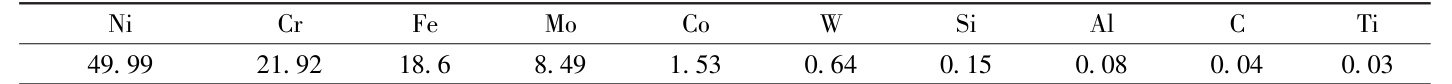

GH3536 合金是一种面心立方镍基高温合金,该合金在高温环境下力学性能优异,且具备良好的可焊性, 被广泛应用于航空发动机热端部件中[1-2]。(剩余8948字)