BDCD850开坏机机架有限元分析及优化设计

打开文本图片集

中图分类号:TG333.5;TB115.1 文献标志码:B

Finite element analysis and optimization design of BDCD850 breaking down mill frame

XIE Erhu1,2,GUO Xianping1,2, ZHANG Tuo

(1.CISDI Equipment Co.,Ltd.,Chongqing ,China; 2.Chongqing Key Laboratory for Metallurgical Intelligent Equipment, Chongqing , China)

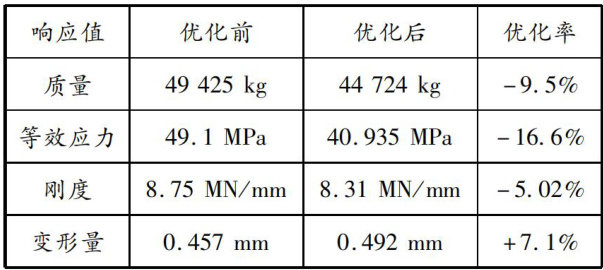

Abstract: To achieve reasonable lightweighting for the breaking down mill frame,the dangerous section shape and the overallsize of the frame is analized.Firstly,the strength,stifness,and hazardous section position of the frame is determined by static strength stress analysis; then,with the goal of minimizing the equivalent stress value,the sub model analysis method and Workbench optimization module are used to optimize the composite fillt size parameters; finally,a response surface model is constructed based on the Box Behnken method,and the analytic hierarchy process and particle swarm optimization algorithm are used to find the optimal combination of rack structural parameters.The overall weight of the optimized frame decreased by about 4701kg ,and the maximum stress at the dangerous section decreased by about 8.845 MPa. The optimization results can reduce production costs by ensuring the strength and stiffness of the billet opening machine frame.

Key words: breaking down mill frame; response surface model; lightweight design; structure optimization;finite element

0引言

随着机械、汽车、能源等制造行业的稳定发展,市场对优特钢产品的需求量迅速增加[1-2],开坏机是优特钢棒线材及大型型钢生产线的重要轧制设备[3],其性能对社会经济的发展发挥着重要的作用。(剩余7302字)