分支井双管封隔器胶筒密封性能研究

打开文本图片集

中图分类号:TE931.2 文献标志码:A doi:10.3969/j.issn.1001-3482.2025.04.005

SealingPerformanceofDual TubingPackerRubberinBranchHoles

XU Jing, MA Lei, YANG Junlong, HAN Cheng, CAO Feng (Zhanjiang Branch, CNOOCChina Co.,Ltd., Zhanjiang 524057,China)

Abstract:Inorder to study thesealing failure of dual tubing packersand reduce the packer failure accident in branch holes,the dual tubing packer rubber in branch holes was studied,and the sealing process of dual tubing packer rubber was simulated by finite element software.The effective sealing coeffcient was proposed to evaluate the sealing performance of the rubber.In addition,the sealing performance of cylindrical,butterfly,and wedge rubbers was studied from the aspects of rubber hardnessand friction coeficient.The results show that the established finite element model can effectively simulate the sealing processof the packer rubber. The comparison with the experiment reveals that the model can meet the engineering requirements. The circumferential contact pressure distribution of the dual tubing packer rubber is not uniform,which will lead to local pressure concentration and reduce the overall sealing performance.A greater rubber hardness and greater friction coefficient mean lower sealing performance. The wedge -shaped rubber scheme involves a certain rubber overlap,which can improve the influence of hardness and friction coefficient on the sealing to acertain extent,with optimal relative effect.The research results can provideareference for the design of a dual tubing packer.

Key words:branch hole; dual tubing packer; rubber; sealing performance; finite element

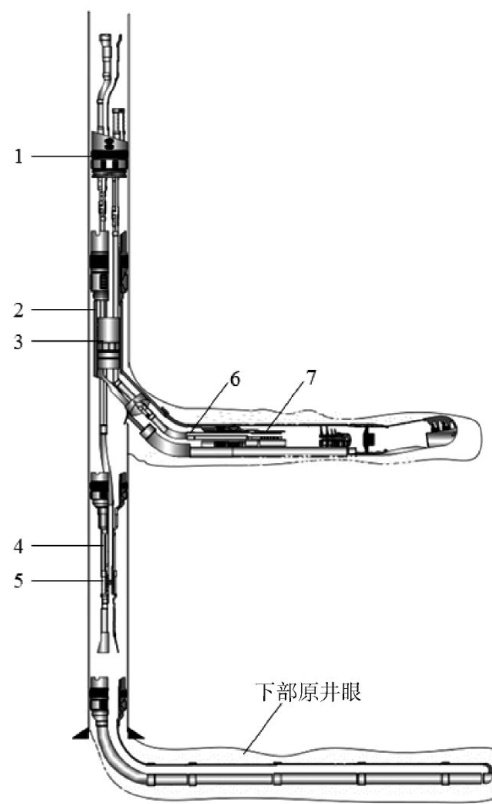

分支并技术在保留原有并眼的条件下,开窗侧钻出新井眼,实现多井眼接触油藏,最大限度地减少新钻井对油藏的影响,尤其当海上油田槽位可用性有限时,与多口单井相比,分支井系统节省了工程开发时间,降低了建井成本,得到广泛应用[1-3]。(剩余6603字)