特深井钻机关键设备预测性维护探索与实践

打开文本图片集

文章编号:1001-3482(2025)04-0001-08

Exploration and Practice of Predictive Maintenance for Key Equipment of DrillingRigsinUltra-DeepWells

ZHANG Zengnian 1,TAO Yun ², JIANG Yuhong², ZHANG Hong 1, XU Jiaxiong 1, MENG Jun',GUO Maolei ²,WANG Junpu 1 (1.Chuanqing Drilling Engineering Co., Ltd., Chengdu 61Oo51, China; 2.Chuanxi Drilling Company,ChuanqingDrilling Co.,Ltd.,Chengdu 61oo51,China)

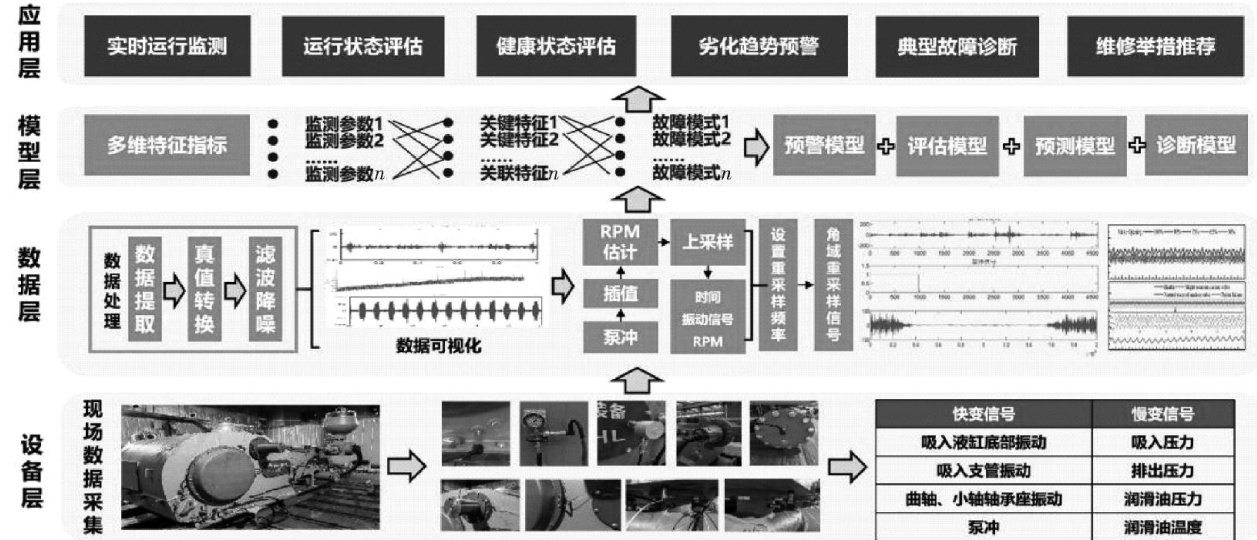

Abstract:To facilitate eficient exploration and development of deep and ultra -deep oil and gas resources,timely and effective equipment maintenance is essential to ensure the safetyand reliability of oil and gas extraction.Moreover,it is urgent to establish an online monitoring and predictive maintenance system for the automated drilling rig in ultra - deep well.By taking the automated drilling rig in the SDCK-1 ultra -deep well as the research objective,firstly,an equipment information system was established using the EISC platform to collect and statistically analyze the service life of vulnerable parts of the target equipment. Then,real-time operating status data collected from the status monitoring model, fault prediction model,and vulnerable parts were exchanged toachieve monitoring of wellhead load,winch operation,drilling pump operation,and top drive vibration.Through practical application in the SDCK-1 well, the equipment failure rate has decreased by 80% ,and theunplanned shutdown maintenance rateis O.The application effect is good,proving the effectiveness of the method.

Key words: drilling rig in ultra-deep well; predictive maintenance; online monitoring; preventive maintenance

我国深层超深层油气资源丰富、潜力大,高效开发深层超深层油气资源是实现我国能源接替战略调整的必然选择,也是未来油气勘探增储上产的重点和热点[1-4]。(剩余6751字)