动静载荷作用下增材制造Ti-6AI-4V合金的力学性能研究进展

打开文本图片集

中图分类号:0347 国标学科代码:13015 文献标志码:A

Research progress on mechanical properties of additive manufacturing Ti-6Al-4V alloy under static and dynamic loading

XIAO Xianfeng1,XU Jianlong1,WU Zuxi1, YE Xiaojun 1,2 ,FU Yanshu1

(1.School ofAdvanced Manufacturing,Nanchang University,Nanchang 33oo31,Jiangxi, China;

2.School ofInformationandArtificial Intelligence,Nanchang InstituteofScienceand Technology, Nanchang,Jiangxi,China)

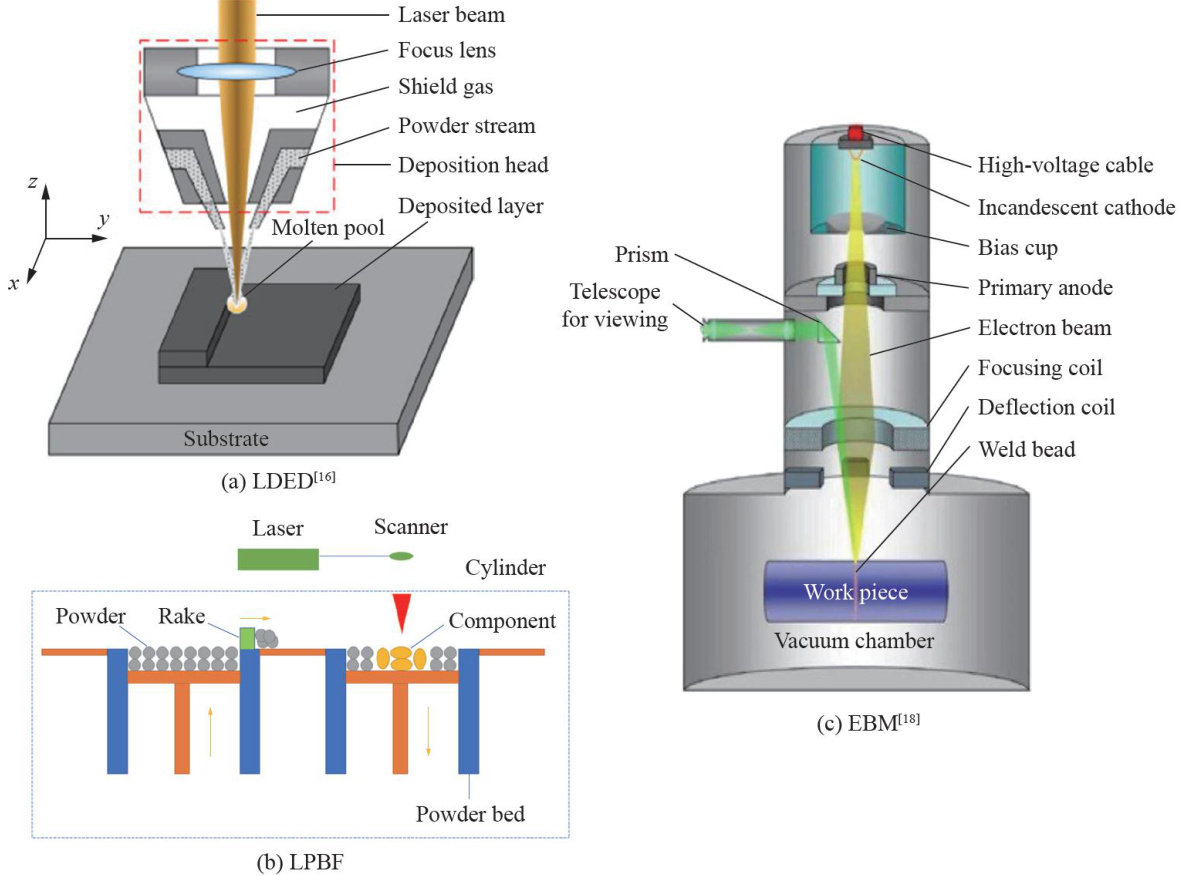

Abstract: With its high design freedom andrapid prototyping capabilities,additive manufacturing (AM)ofers significant advantages inmanufacturing criticalcomponents withcomplex geometries for theaerospaceanddefense industries.Ti-6Al-4V alloy,leveragingitsexceptionalcombinationoflowdensity,ighspecificstrength,andcrepresistance,areextensively employed incritical structures that are frequentlysubjected to impact loading inaerospace and defense systems.A thorough understandingof themechanical propertiesandunderlying mechanismsof theaditivelymanufacturedTi-6Al-4Vallyunder staticanddynamic loading iscrucial forenhancingtheserviceperformanceof thesecomponents.This paper systematically reviews and summarizes the latest advancements in the mechanical response of AMTi-6Al-4Vtitanium aloys.Firstly,a brief overview of the classification and working principles of typical metal aditive manufacturing (AM)technologies is provided. Subsequently,research eforts on thequasi-static tensile and dynamic compressive propertiesof additively manufactured Ti-6Al-4V titanium alloyaresystematicallyreviewed,followed byacomparativeanalysisof itsmechanical performance against cast and forged Ti-6Al-4Vcomponents.Furthermore,the mechanismsof corelation between the microstructure and mechanical behaviorsoftypical metaladitive manufactured itanium alloys.Additionally,thecommonlyusedpost-processing techniques to mitigate the anisotropic mechanical response of AM Ti-6Al-4V alloy under static loading are summarizes.

Keywords: additive manufacturing; Ti-6Al-4V; dynamic and static loading; mechanical properties; anisotropy

根据美国材料与试验协会(American Society for Testing and Materials,ASTM)对增材制造(additivemanufacturing,AM)的定义——与减材制造相反,依据3D模型数据,通过将材料一层一层地堆叠以制造所需部件,增材制造也被称为3D打印、叠层制造和自由成形制造等[1]。(剩余45490字)