热处理对沉积态纳米TiC/7034复合材料组织性能的影响

打开文本图片集

中图分类号:TG146.2 文献标志码:ADOI: 10.12475/aie.20250407

Effect of Heat Treatment on Microstructure and Properties of As-deposited Nano-TiC/7034 Composite Materials

WANG Yong1 HE Chenghao² MI Gaoyang² HONG Chunquan³ ZHENG Lin² (1.Shanghai Space Propulsion Technology Research Institute, Shanghai 2O11O5, China

2.School of Materials Science and Engineering, Huazhong University of Science and Technology, Wuhan

430074, China3.School of Mechanical Science and Engineering, Huazhong University of Science and Technology, Wuhan 430074, China )

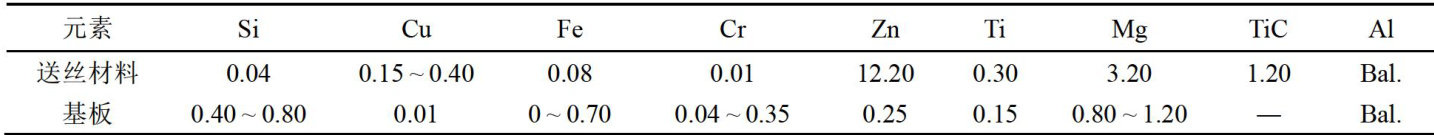

Abstract:Nano-TiCparticle-reinforced7034aluminum matrixcomposites exhibit high strength,highhardnessand low density,makingthmpromising lightweight materials.However,tehighontentoflow-boilingpontelements(Zn,Mgin7034 aluminumaloyleadtobolingadevaporationinthehgtemperaturemoltenpool,esultigindefectssuchasporesadcacks, which degrade mechanical properties.Toaddress this,a swing laser-arc hybrid additive manufacturing processwas employed to fabricate nano-TiC-reinforced 7034aluminummatrix composites.The efectsof solutiontreatmentandsolution-agingtreatmenton microstructureand mechanicalpropertieswereinvestigated.Theresultsidicate thatsolutiontreatment promotesthedissolutionof MgZn2 phases.Subsequent aging treatment after solution treatment leadsto amore uniform distribution and finer sizeof secondary phases, increasing the ultimate tensile strength to 569.83MPa with an elongation of 1.44% . By optimizing the solution temperature and aging process,the tensile strength of the composite was improved by 70% 二

Keywords: nano-TiC particles; 7034 aluminum matrix composites; laser-arc hybrid aditive manufacturing; solution-aging treatment; heat treatment

0 引言

颗粒增强铝基复合材料是将小尺寸颗粒(多为陶瓷颗粒)添加到铝合金中形成的复合聚集体。(剩余14265字)