含钒铬泥二次资源综合利用技术研究

打开文本图片集

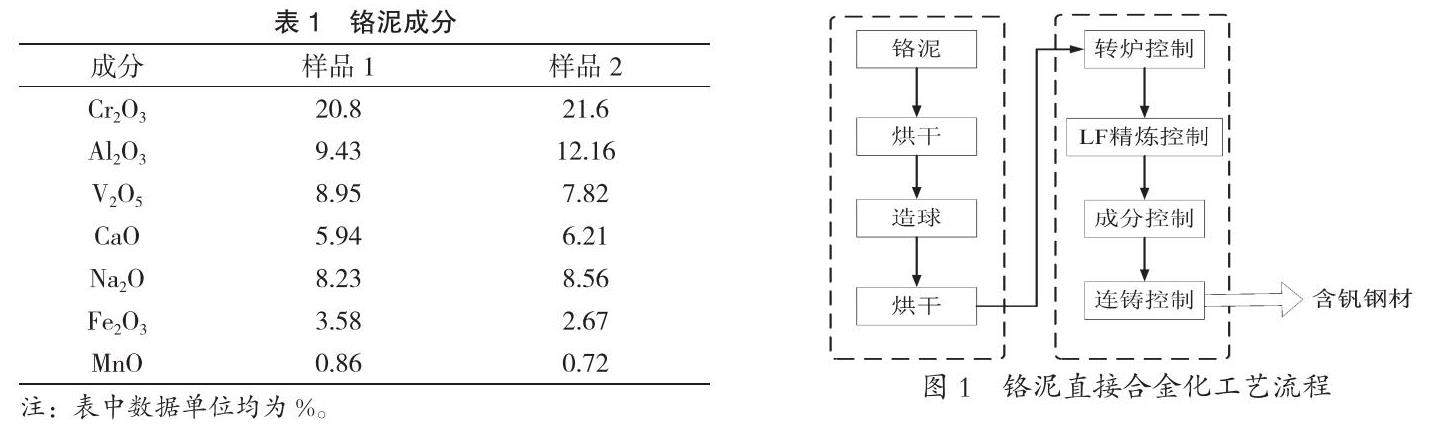

摘要:针对含钒铬泥的资源特性,本研究开发了铬泥直接合金化技术及铬泥碱性液相氧化钒铬清洁分离技术。研究表明,钒和铬的平均回收率分别达到90%和80%,该组合工艺生产出合格的HRB400E钢,获得合格的钒酸钠、铬酸钠产品,实现了含钒铬泥中有价元素的高效利用。

关键词:铬泥;钒;铬;资源利用

中图分类号:TF81 文献标识码:A 文章编号:1008-9500(2023)03-00-04

DOI:10.3969/j.issn.1008-9500.2023.03.019

Abstract: According to the resource characteristics of vanadium and chromium sludge, the direct alloying technology of chromium sludge and the clean separation technology of vanadium and chromium by alkaline liquid phase oxidation of chromium sludge have been developed in this study. The research shows that the average recovery of vanadium and chromium reaches 90% and 80% respectively, this combined process produces qualified HRB400E steel, obtains qualified sodium vanadate and sodium chromate products, and realizes efficient utilization of valuable elements in vanadium and chromium sludge.

Keywords: chromium sludge; vanadium; chromium; resource utilization

铬是钒钛磁铁矿的伴生元素,在现有钒渣钠化焙烧提钒工艺中,有10%~20%的伴生铬与钒同步浸出至液相,铵盐沉钒后,浸出的铬及未能回收的钒留在沉钒废水中,它以Cr6+的形式存在。(剩余2309字)