硫铁矿精矿脱砷脱硫试验研究

打开文本图片集

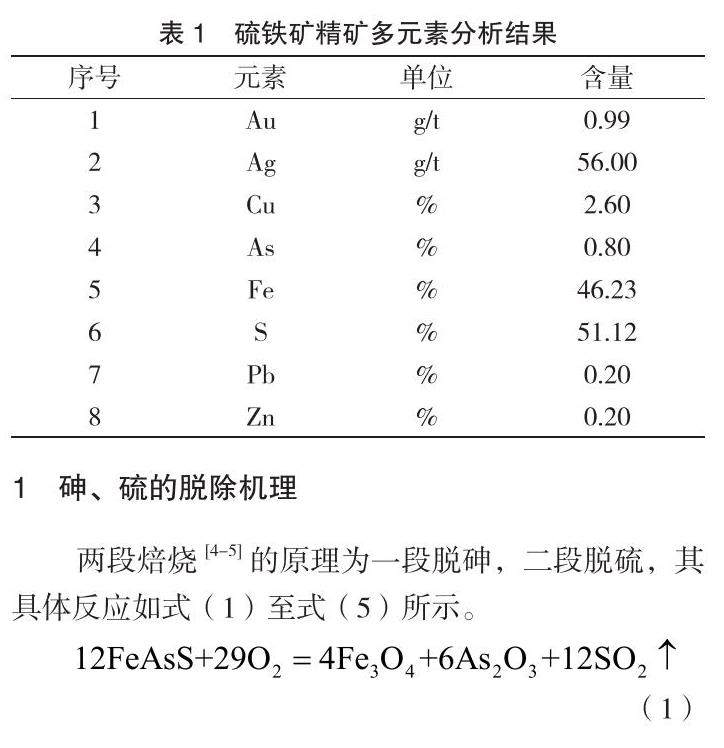

摘要:硫铁矿制酸会产生烧渣,其砷含量与硫含量影响后续产品的质量。本文通过试验研究,确定适宜条件,对硫铁矿精矿中的砷、硫进行脱除。试验结果表明,选择一段焙烧,焙烧温度为900 ℃,焙烧时间为2 h时,脱砷脱硫效果很好。

关键词:硫铁矿精矿;脱砷;脱硫

中图分类号:TF831 文献标识码:A 文章编号:1008-9500(2023)03-000-03

DOI:10.3969/j.issn.1008-9500.2023.03.003

Abstract: Slag will be generated during sulfuric acid production from pyrite, and its arsenic content and sulfur content can affect the quality of subsequent products. In this paper, the suitable conditions are determined to remove arsenic and sulfur from pyrite concentrate through experimental research. The experiment results show that the effect of arsenic removal and desulfurization is very good when the roasting temperature is 900 ℃ and the roasting time is 2 h.

Keywords: pyrite concentrate; arsenic removal; desulphurization

硫铁矿是我国重要的硫资源,硫铁矿制酸过程中排出大量含铁和其他有价金属的烧渣。(剩余2529字)