SPA-H强度偏低分析与研究

打开文本图片集

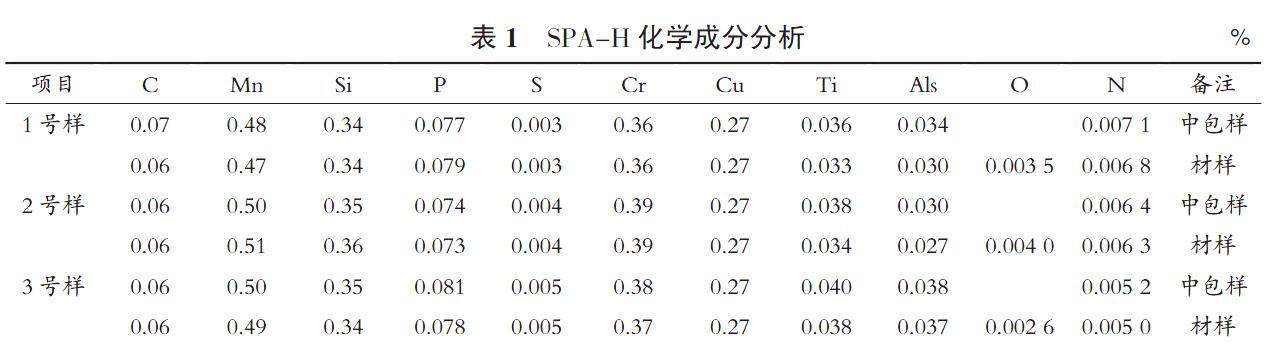

摘 要:对SPA-H工艺过程进行跟踪,结合金相组织及非金属夹杂物分析强度不稳定的原因。研究分析表明,SPA-H强度偏低主要集中在连铸开浇和热换炉次,因保护浇铸不当,造成板坯成分N含量偏高,有效Ti含量降低,导致钢种强度偏低。

关键词:强度;氮;耐候钢;有效钛

ANALYSIS AND RESEARCH ON THE LOW STRENGTH OF SPA-H

Bu He Li Aibin Qu Xiaojian Huang Richeng

(Guangxi Shenglong Metallurgical Co., Ltd. Fangchenggang 538000,China)

Abstract:This article analyzes the reasons for the instability of SPA-H strength by tracking the process, metallographic structure, and non-metallic inclusions. The research analysis of SPA-H shows that the low strength is mainly due to the continuous casting and heat exchange furnace. Improper protective casting results in a higher N content in the slab composition and a decrease in effective Ti content, leading to a lower strength of the steel grade.

Key words: strength; nitrogen; SPA-H; effective titanium

0 前 言

耐海洋性气候腐蚀钢板(以下简称“耐候钢”)是制造集装箱的主要材料,其中热轧SPA-H钢板因具有良好的耐蚀性而成为集装箱制造业用量最多的钢种之一[1]。(剩余2921字)