本钢特钢小棒材表面划伤改善

打开文本图片集

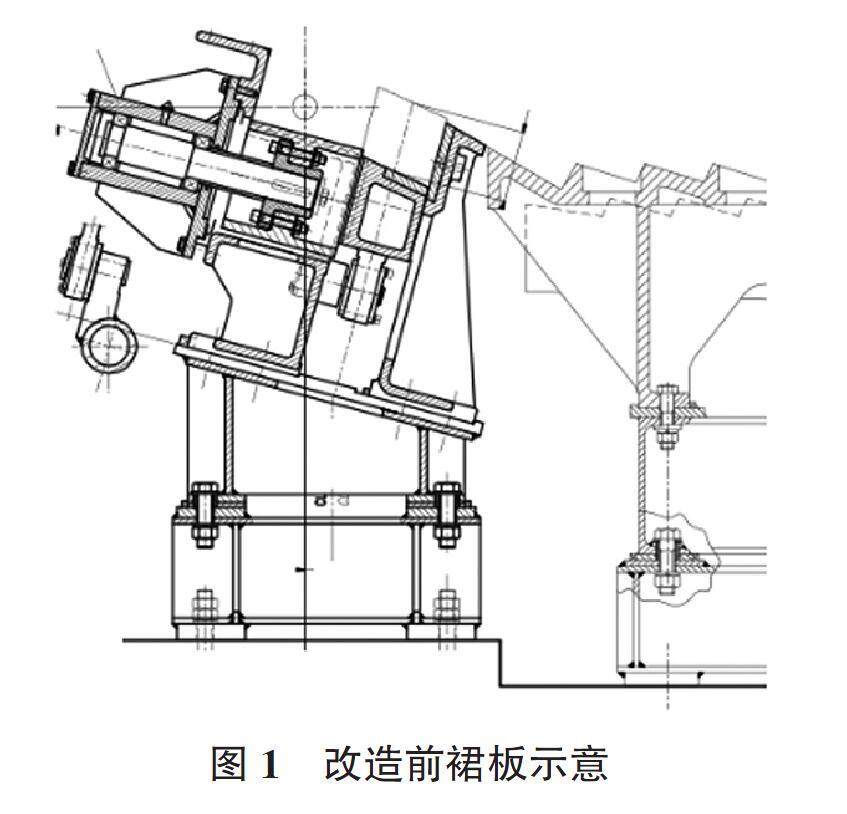

摘 要:分析本钢特钢小棒材表面划伤产生的原因,通过对轧机工装精度提升的管控,空过辊道两侧加装惰轮,设计制作裙板耐磨锥轮,有效解决小棒材表面划伤问题,显著提升成品表面质量,缩短交货期,降低生产成本。

关键词:小棒;划伤;工装;辊道;裙板;冷床

IMPROVEMENT OF SCRATCHE DEFECT ON SMALL-LEVEL BAR PRODUCTION LINE IN BENXI SPECIAL STEEL

Wang Dong1 Li Mingming2 Yu Haixiao2

(1. Special Steel Division of Bengang Plate Co., Ltd. Benxi 117000,China;

2.Bensteel Technology Center Benxi 117000,China)

Abstract:This article analyzes the causes of scratches on the surface of small-level bars in Benxi special steel. By improving the control of rolling mill tooling accuracy, idler wheels are installed on both sides of the roller table, and wear-resistant cone wheels of skirt plate are designed and made, which effectively solve the problem of scratches on the surface of small-level bars, significantly improve the surface quality of finished products, shorten the delivery time and reduce the production cost.

Key words: small-level bar; scratch; quality of tooling;roller table;skirt plate; cooling bed

0 引 言

2022年9月本钢特钢小棒线进行升级改造,在原有设备的基础上新增一台步进梁式加热炉、四架Kocks轧机、更新了四段穿水以及三座飞剪、裙板等设备,改造后小棒线具备生产φ12 ~ 80 mm圆60万t优特钢的生产能力。(剩余2712字)