LF精炼无氟渣系生产Q345qE生产实践

打开文本图片集

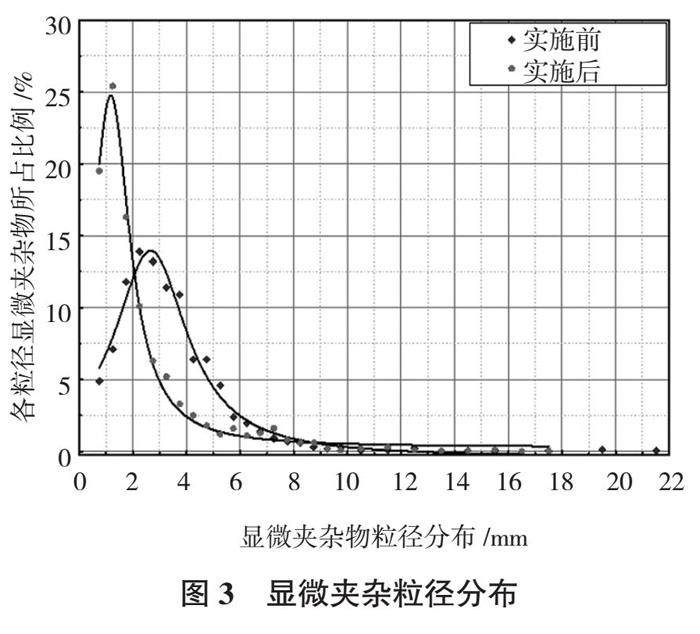

摘 要:根据不同精炼渣系的特点,唐山中厚板公司选择无氟的CaO-Al2O3-SiO2渣系,同时优化转炉脱氧工艺,采用循环渣利用技术,实现了精炼工序取消萤石。生产实践表明,该渣满足了唐山中厚板材有限公司BOF-LF-CC工艺生产Q345qE的要求,为高效生产和清洁生产奠定了基础。

关键词:LF;无氟精炼渣;脱氧;脱硫

PROCESS STUDY ON CANCELLING FLUORITE OF STEEL-REFINING BY LF

Luan Wenlin Liu Zhiyuan Wang Chongjun Yao Jingwen

(Tangshan Heavy Plate Co., Ltd., Hebei iron and Steel Group Tangshan 063000,China)

Abstract:Based on the characteristics of different refining slag systems, Tangshan Heavy Plate Co Ltd has chosen the fluorine-free CaO-Al2O3-SiO2 slag system, optimized the converter deoxygenation process, and adopted cyclic slag utilization technology to achieve the elimination of fluorite in the refining process. The industrial practice showed that the slag was suitable for producing Q345qE in Tangshan Heavy Plate Co Ltd, and also establishing the foundation of high efficiency production and cleaner production.

Key words: LF; refining slag without CaF2; desulphurization; deoxidatio

0 引 言

LF精炼炉使用精炼渣主要有钙铝渣系和钙氟渣系两种[1],其中CaO-CaF2渣系使用较为普遍,该渣系的特点是脱硫、脱氧能力较为突出,渣中CaF2可以显著的降低脱硫渣的熔点,改善炉渣的流动性。(剩余3115字)