预应力RC-UHPC组合箱梁正截面抗裂性能

打开文本图片集

中图分类号:U443.35 文献标志码:A 文章编号:2096-6717(2025)04-0058-08

Crack resistance of prestressed RC-UHPC composite box girder

LIN Shangshun 1 ,Jl Bangchong 1 , XIA Zhanghua 2 ,YANG Yang 2 ,LIN Jianfan 3 ZHAO Jinbing4

(1.FujianProvincialKeyLaboratoryofCivil Engineering New Technology and Information Technology,Fujian UniversityofTechnology,Fuzhou 35Ol18,P.R.China;2.SchoolofCivil Engineering,Fuzhou University,Fuzhou ,P.R.China;3.FujianProvincial TransportationResearch Institute Co.,Ltd,Fuzhou35oo04,P.R.China; 4.Haoyao Times(Fujian) Group Co.,Ltd,Fuzhou 35OOO2,P.R.China)

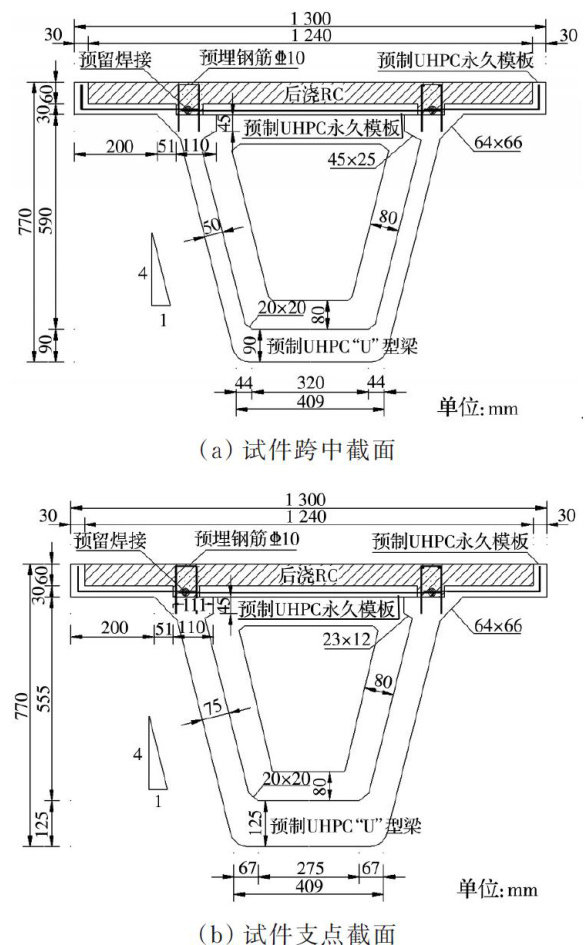

Abstract: The prestressed RC-UHPC composite box girder with high tensile strength and corrosion-resistant ultra-high performance concrete (UHPC)as the web and bottom plate and reinforced concrete (RC)as the top plate was proposed,and a specimen was fabricated. The flexural test was carried out to analyse the crack development pattern and damage mode of the specimen; the finite element software Was used to simulate the test,and the calculation accuracy was verified by comparing the finite element calculation results with the testing data,on thebasisof which19 finite element analysis models were established toanalyse the influence of various parameters on the cracking moment; relevant codes and existing literature were used to investigate the cracking moment of the prestressed RC-UHPC composite box girder. The results show that: the first crack appeared when the specimen was loaded to about 33.3% of ultimate load;the cracking moment was influenced by the prestressing bar tension factor,the prestressing bar reinforcement ratio and the tensile strength of UHPC; the cracking moment calculation method based on the conversion sectionand the crack width calculation formulas in DBJ 43/T 325—2O17 were used to calculate the cracking moment and crack width of the prestressed RC-UHPC composite box girder,respectively,and the calculated values agreed well with the testing and FE results.

Keywords: bridge engineering;composite beam;ultra-high performance concrete; cracking moment; crack width

箱梁是桥梁常用的主梁形式,钢箱梁具有自重轻、施工快等优点,但容易出现涂装劣化、钢材腐蚀、桥面板易损坏等病害],涂装与养护费用较高;钢-混凝土组合梁力学性能优秀、自重轻,但存在钢材疲劳、剪力键易失效、不容易养护及养护费用高的问题[2-3];混凝土梁自重大,吊装难度大,限制了其在城市桥梁中的应用,PC箱梁也普遍存在腹板开裂、跨中下挠等病害4。(剩余10498字)