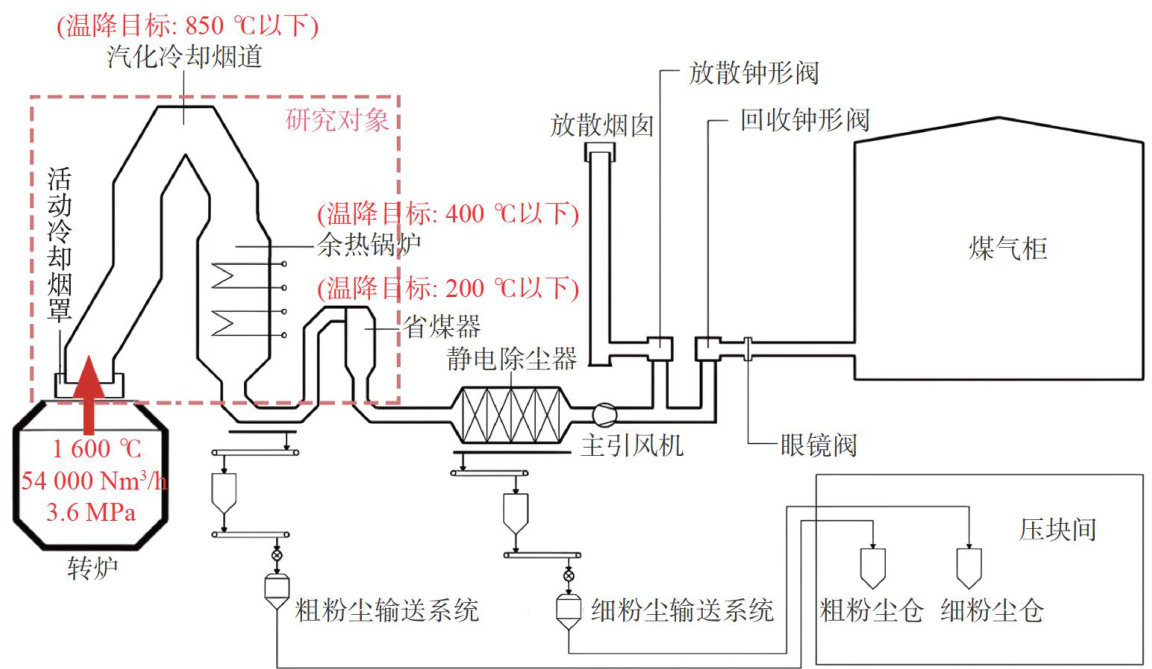

转炉烟气全干法余热回收系统数值模拟及结构优化

打开文本图片集

中图分类号:F830 文献标志码:A

Abstract: Addressing the research gap in the study of the full flow field of the all-dry flue gas waste heat recovery system for basic oxygen furnaces, a 80 t converter gas all-dry heat recovery system was taken as the research object. Using numerical simulation combined with theoretical calculations, a simplified modeling approach suitable for this system was explored, and a numerical simulation and analysis of the entire heat exchange process of the flue gas was conducted,and the optimization scheme of the system structure was discussed. The results show that replacing the water-cooled wall with a zigzag wall and substituting parallel circular tubes for heat exchange screens can significantly reduce the number of grids while ensuring data accuracy. During the gas flow process in the system, the flue gas uniformity initially decreases and then increases, while the temperature drops rapidly at first and then more slowly, with multiple low-velocity zones near the pipe walls. For the medium-temperature heat exchange section, videlicet waste heat boiler I and II, which use water-cooled walls and heat exchange screens for heat transfer, increasing the number of heat exchange screens is more effective in improving heat transfer efciency than simply enlarging the pipe diameter. For the low-temperature heat exchange section that only uses heat exchange screens for heat exchange, videlicet waste heat boiler II and highlow temperature economizer, considering the pressure drop and heat exchange effect, choosing the spacing of heat exchange panels of 96~141mm is reasonable.

Keywords: all-dry waste heat recovery; numerical simulation; model simplification; heat transfer characteristics

转炉炼钢是当今世界上最主要的炼钢方法,我国也不例外[1]。(剩余12331字)