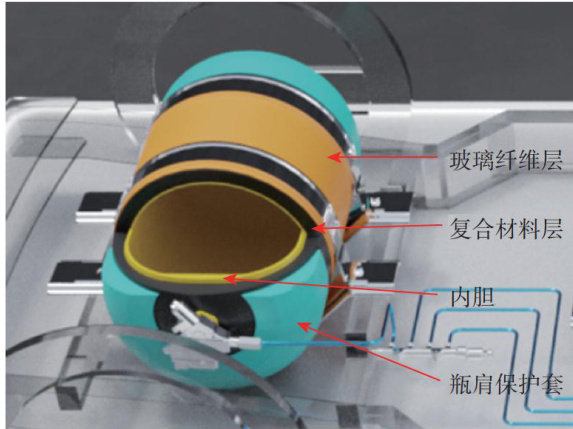

复合材料气瓶关键参数优化设计

打开文本图片集

中图分类号:TK91 文献标志码:A

Abstract: High-pressure gaseous hydrogen storage is currently the mainstream technical solution for onboard hydrogen storage. Compared to metal gas cylinders,composite gas cylinders offer higher storage density and better safety performance.In recent years, with the maturation of manufacturing technology, the application proportion of composite gas cylinders has gradually increased. A design and modeling method for composite gas cylinder ply is proposed in this study. By changing the head shape and adjusting the winding process, increased efective volume of the cylinder and reducing fiber usage is achieved. Results shows that the winding layer thickness designed using empirical formulas contains redundancy and can be reduced based on first principal stress results at characteristic locations. The ply sequence affects fiber stress distribution,and it is suggested that helical winding layers should be concentrated near inner wall of the liner. Using ellipsoidal heads and reducing the average winding angle helps control the gas cylinder's volumetric change rate. This design method has been verified through single-product testing and provides valuable reference for development of similar products

Keywords: composite gas cylinder; hydrogen storage cylinder; winding angle; layer order

发展氢能是交通行业实现“低碳”自标的重要途径。(剩余6915字)