本钢特钢中棒材头部弯曲改善

打开文本图片集

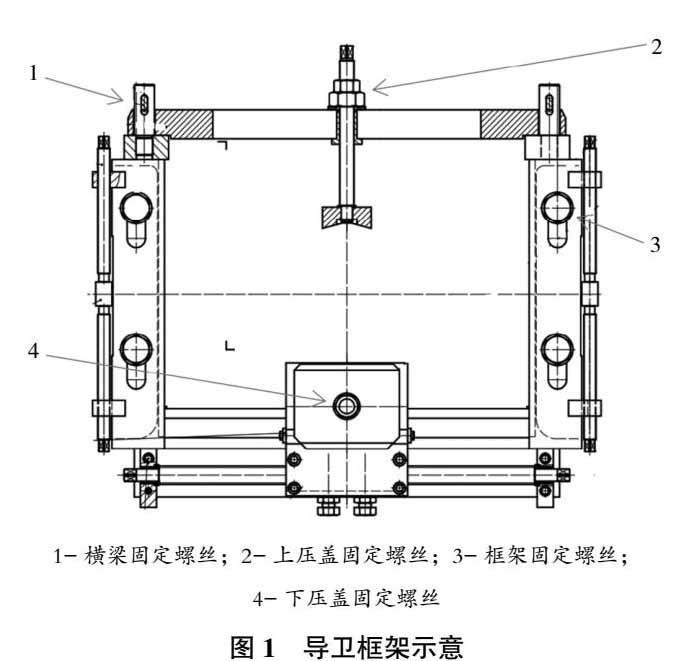

摘 要:分析本钢特钢中棒材头部弯曲产生的原因,通过优化加热工艺、新增定径轧制工艺、改进出入口导卫固定方式与出口导卫内堂尺寸,有效降低了中棒材头部弯曲度及弯曲比例,显著提升钢材外观质量,减少金属损失,降低了生产成本。

关键词:头部弯曲;加热;轧机;导卫;定径轧制

Abstract:This article analyze the reasons for the bending of the head of the bars in Benxi special steel. By optimizing the heating process, adding a fixed diameter rolling process, improving the fixing method of the inlet and outlet guide and the size of the outlet guide, the bending degree and proportion of the head of the bar have been effectively reduced, significantly improving the appearance quality of the steel, reducing metal loss, and lowering production costs.

Key Words: head bending; heating; rolling mill; guide and guard; fixed diameter rolling

0 引 言

本钢特钢事业部中棒产线始建于2007年,于2019年进行升级改造,改造后主要装备有2座步进梁式加热炉,1架φ1 150 mm二辊可逆式开坯机,3架850无牌坊高刚度轧机、1台液压剪,4架480与5架576短应力线精轧机,1座编组台架,3台磨切锯,1座齿条式步进冷床。(剩余3484字)