转炉低温低氧工艺降低碳排放研究与应用

打开文本图片集

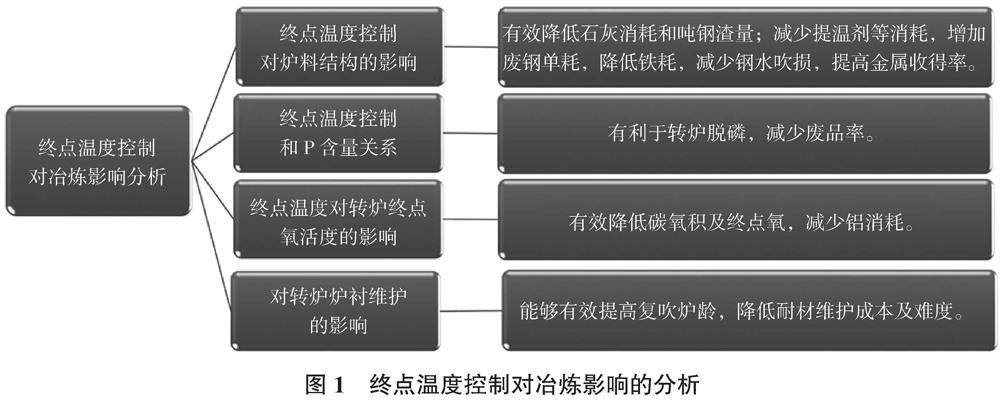

摘 要:本钢炼钢厂受工序之间运输限制,对出钢温度要求极为严格,各项炼钢指标控制水平较低,碳排放水平较高,为了解决此类问题,通过工艺技术研发与创新,推进转炉低温低氧出钢控制技术,减少能源消耗,提高钢水质量,同时降低脱氧铝的消耗,降低钢铁料消耗,提高负能炼钢指标,减少碳排放,实现碳达峰碳中和。

关键词:转炉;低温低氧;负能炼钢;碳排放

RESEARCH AND APPLICATION OF LOW TEMPERATURE AND LOW OXYGEN CONVERTER PROCESS TO REDUCE CARBON EMISSIONS

Xue Changjiang Zhang Hongbi Li Quan Cong Haitao

(Steelmaking Plant of Benxi Steel Plate Co., Ltd. Benxi 117000, China)

Abstract:The steelmaking plant of Benxi Iron and Steel Co., Ltd. is restricted by the transportation between processes, and has extremely strict requirements on tapping temperature. The control level of various steelmaking indicators is low, and the carbon emission level is high. In order to solve such problems, through process technology research and development and innovation, the control technology of converter low temperature and low oxygen tapping is promoted, so as to reduce energy consumption, improve the quality of molten steel, reduce the consumption of deoxidized aluminum, reduce the consumption of steel materials, improve the negative energy steelmaking indicators, and reduce carbon emissions, Achieve peak carbon neutralization.

Key words:Converter; Low temperature and hypoxia; Negative energy steelmaking; Carbon emission

0 前 言

本钢炼钢厂作为百年企业,生产工序受布局限制,工序之间运输时间长,对出钢温度要求极为严格,高氧化性及高温钢水对转炉脱磷、炉况维护、钢水质量、炼钢工序成本及提高废钢比都有直接影响。(剩余4564字)