高端工业纯铁脱锰工艺研究

打开文本图片集

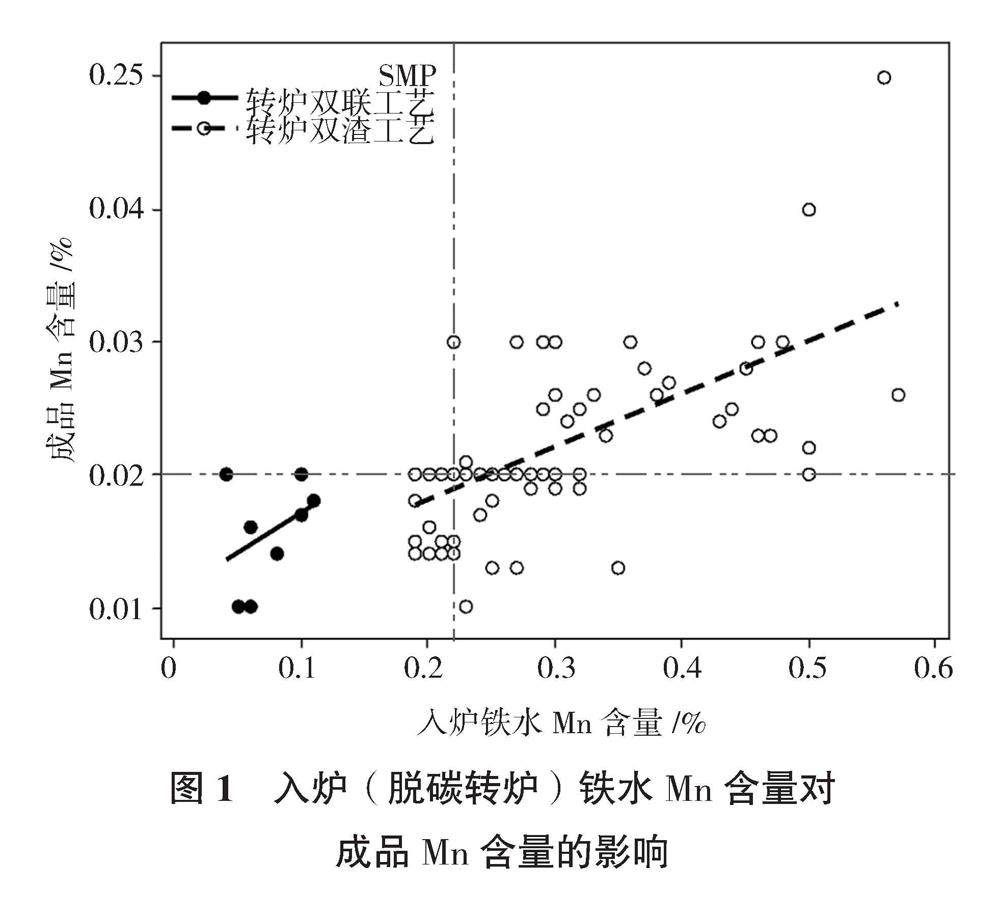

摘 要:高端工业纯铁要求W(Mn)≤0.02%,Mn含量的控制是主要难点。为此分析了铁水Mn含量、转炉终点温度、转炉终点氧活度、终渣碱度以及钢包渣成分对Mn含量控制的影响。通过合理控制铁水Mn含量、转炉终点温度、转炉终点氧活度、终渣碱度以及钢包渣成分,实现成品W(Mn)≤0.02%的稳定控制。

关键词:工业纯铁;脱锰工艺;锰分配比;精炼渣

RESEARCH ON HIGH-END INDUSTRIAL PURE IRON MANGANESE REMOVAL PROCESS

Li Yang

(Tangshan Iron & Steel Group Co. Ltd. Tangshan 063105,China)

Abstract:High end industrial pure iron requires W(Mn)≤0.02%. The control of Mn content is the main difficulty. In this paper, the effects of Mn content in hot metal, converter end temperature, oxygen activity at converter end point, basicity of converter final slag and ladle slag composition on Mn content control are analyzed. The stable control of W (Mn) ≤ 0.02% can be achieved by reasonable control of Mn content in hot metal, end point temperature of converter, oxygen activity of converter end point, basicity of converter final slag and composition of ladle slag.

Key words:industrial pure iron; manganese removal process; manganese distribution ratio; refining slag

0 前 言

工业纯铁作为一种重要的钢铁基础材料,主要用于冶炼各种高温合金、耐热合金、精密合金、马氏体时效钢等航空航天、军工和民用合金或钢材[1]。(剩余5526字)