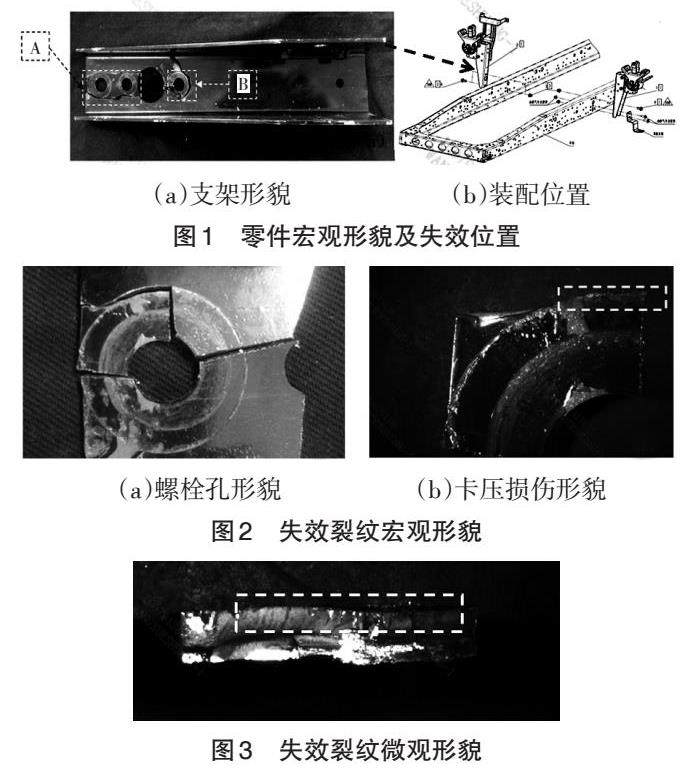

支架类零部件失效模式分析与改进建议

打开文本图片集

摘要:以支架类零件失效为主要研究对象,针对支架螺栓孔卡压损伤引起的失效、螺栓孔微动磨损导致零部件失效、支架刚性突变引起的失效、零部件制造缺陷(毛刺、微裂纹)以及焊接类支架焊缝失效进行了失效分析,着重从零件结构特点、裂纹源形貌进行了研究,提出了改进建议。

关键词:支架 零件失效 应力集中 裂纹源 疲劳断口

中图分类号:U466 文献标识码:B DOI: 10.19710/J.cnki.1003-8817.20220241

Abstract: With bracket parts as the main research object, this paper mainly analyzed the various kinds of failures caused by the clamping damage of bolt holes, fretting wear of bolt holes, sudden change of bracket rigidity, the manufacturing defects (burrs, microcracks) and the failures of welded brackets, emphasizing on the research on structural characteristics of parts, the morphology of crack sources for proposed improvement recommendations.

Key words: Support, Part failure, Stress concentration, Crack source, Fatigue fracture

1 前言

在汽车众多零部件中,支架类零件占比很大,此类零部件主要起到连接、支撑作用。(剩余4386字)