联邦学习的社群化制造韧性能力预测建模

打开文本图片集

中图分类号:TP166文献标志码:ADOI:10.7652/xjtuxb202508002 文章编号:0253-987X(2025)08-0011-09

Federated Learning-Based Predictive Modeling of Resilience Capability in Social Manufacturing

ZHANG Fuqiangl'²,WANG Haojiel'²,HUI Jizhuang1²,DING Kai 1,2 (1.Key LaboratoryofRoad Construction Technologyand Equipmentof MOE,Chang'an University,Xi'an 71oo64,China; 2. Institute of Smart Manufacturing Systems,Chang'an University,Xi'an 71Oo64,China)

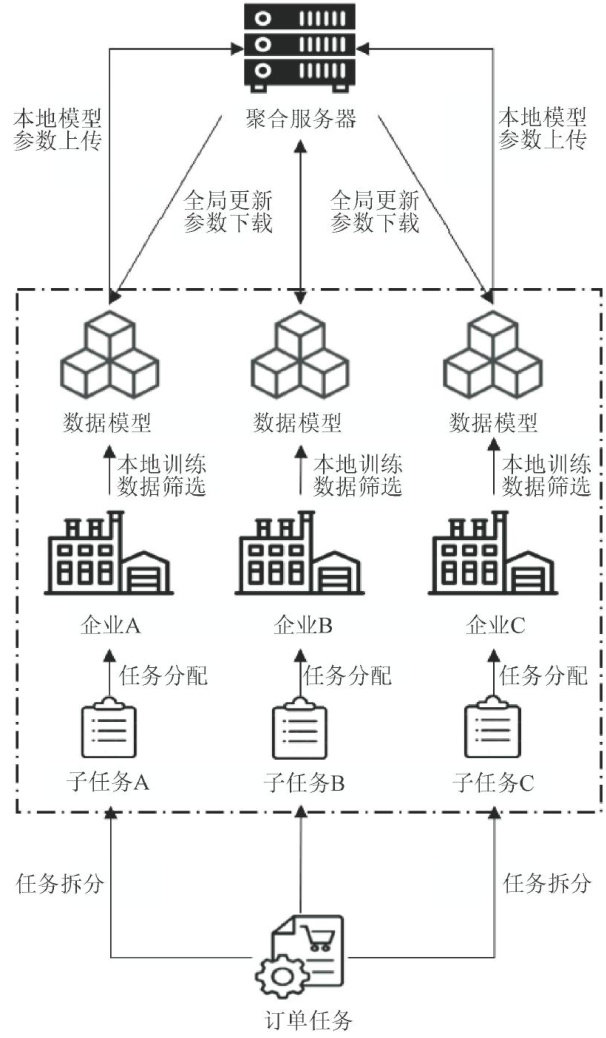

Abstract: Considering the characteristics of decentralized resource layouts in social manufacturing, as well as the issues of data privacy and information silos faced by traditional centralized modeling, this paper proposes a resilience capability prediction framework based on federated learning. The framework analyzes the impact of various factors on product processng time from multiple perspectives. First, considering different interruption scenarios in production processes, a working hour disturbance model is established with the order delivery cycle as the objective function to calculate loss time. Subsequently,a federated learning network model is constructed based on a distributed learning paradigm. Next,a federated mini-batch gradient descent (FedMBGD) algorithm is designed, detailing the algorithmic process and performing local training. Finally, the resilience capability of social manufacturing is predicted in conjunction with the working hour disturbance model and the algorithm. The feasibility and effectiveness of the proposed algorithm are validated through comparisons with other algorithms.The research results indicate that the proposed algorithm significantly enhances convergence and optimization capabilities, raising prediction accuracy to over 90% . Furthermore,it enables dynamic and precise prediction of social manufacturing resilience without sharing raw data, resolving the conflict between data privacy and collaborative modeling. This study provides theoretical references for predicting resilience capabilities in social manufacturing models and offers guidance for algorithm training with private data,parameter uploading,and information sharing.

Keywords: social manufacturing; working hour disturbance; federated mini-batch gradient descent; manufacturing resilience capacity prediction

在全球化浪潮与先进制造技术的双重驱动下,生产制造业的资源布局呈分散化趋势,这要求多个领域的制造资源必须实施深度重组与优化配置,并且转型为一个高度集成化且各环节间紧密相连、相互依存的生态系统,其稳定性和抗风险能力研究至关重要[1]。(剩余12869字)