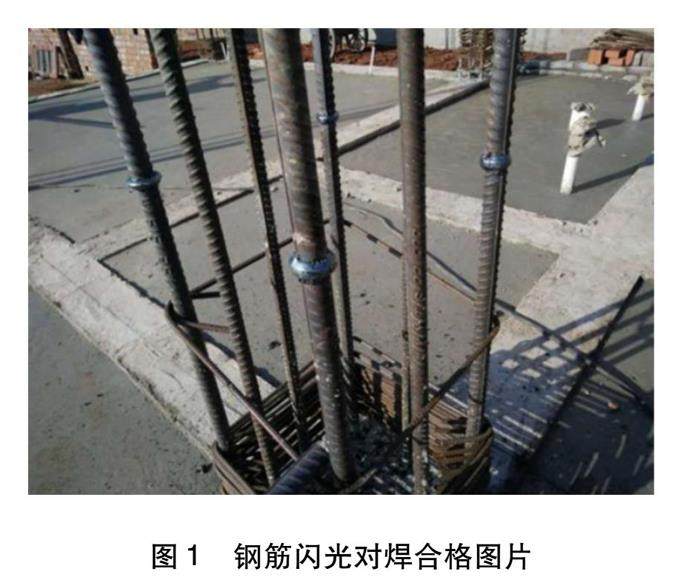

预制梁钢筋闪光对焊的质量控制

打开文本图片集

摘要: 钢筋焊接采用闪光对焊,焊接接头存在一次性抽检率合格率较低,导致施工中出现返工,既延误了工期、又浪费了人力物力,同时留下了质量隐患。文中从钢筋闪光对焊接头质量检验及验收几个方面展开论述。

关键词: 钢筋闪光对焊、连续闪光焊、原因分析及要因确认、制定对策

中图分类号: TG 47

Quality control of flash butt welding of precast beam reinforcement

XU Long

(Jingzhou Huacheng Construction Engineering Quality Inspection Co., Ltd.,Jingzhou,434001 Hubei,china)

Abstract: Flash butt welding is used in the welding of steel bars, and the one-time spot inspection rate of the welded joints is low,Lead to rework in the construction, not only delayed the construction period, but also a waste of human and material resources,And left a quality hazard.In this paper, the quality inspection and acceptance of flash butt welding of Steel Bar are discussed.

Key words: Steel Bar flash butt welding, continuous flash welding, cause analysis and cause confirmation, make countermeasures

0 前言

闪光对焊广泛用于碳钢、合金钢、有色金属的管、棒、板、型材之间的对焊或异类金属之间的对焊[1-6]。(剩余4010字)