H11Mo模具钢电渣锭补缩工艺应用研究

打开文本图片集

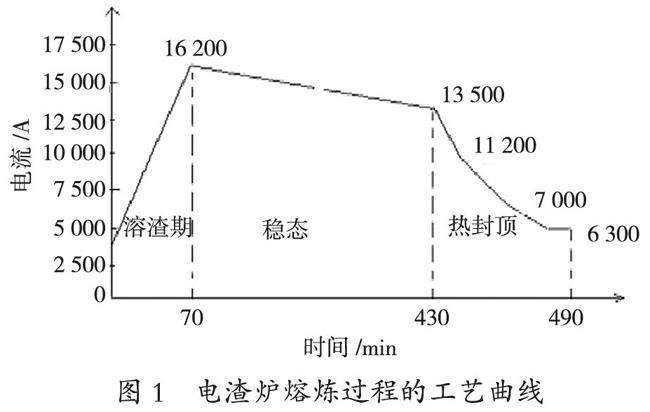

摘要:张宣科技特材研制公司新开发H11Mo模具钢,但电渣锭头部的渣沟与缩孔较深,自耗电极剩余多。有必要分析电渣重熔热封顶阶段自动控制补缩工艺的不足,提出适合、有效的补缩工艺控制新方式。经实践验证,生产问题得以解决,切损量减少,成材率提高。

关键词:模具钢;电渣锭;补缩工艺;热封顶;渣沟;缩孔

中图分类号:TF14 文献标识码:A 文章编号:1008-9500(2024)05-00-03

DOI:10.3969/j.issn.1008-9500.2024.05.018

Research on the Application of H11Mo Mold Steel Electroslag Ingot Shrinkage Process

JIN Hongwei

(Zhangxuan Technology Special Materials Company, Zhangjiakou 075100, China)

Abstract: Zhangxuan Technology Special Materials Company has newly developed H11Mo mold steel, but the slag groove and shrinkage hole at the head of the electroslag ingot are deeper, leaving more consumable electrodes. It is necessary to analyze the shortcomings of the automatic control shrinkage process during the hot capping stage of electroslag remelting, and propose a suitable and effective new method for shrinkage process control. Through practical verification, production problems have been solved, cutting loss has been reduced, and yield has been improved.

Keywords: mold steel; electroslag ingots; shrinkage process; hot capping; slag ditch; shrinkage hole

H11Mo模具钢是空冷硬化型热作模具钢,具有高硬度和高韧性,满足热作模具钢作业环境要求,因此在压铸行业广泛应用。(剩余2833字)