管材冲孔工艺分析与模具优化设计

打开文本图片集

摘 要:以空心管材的支架零件为例,介绍了零件的结构特点,分析了支架零件的冲孔工艺,通过建立数学模型,分析了冲孔尺寸与管材直径等相关参数的关联性,及空心管材冲孔后的强度影响因素,实现了空心管材应用产品的优化设计。

关键词:空心管材;冲孔;工艺分析;优化设计

中图分类号:TG386

文献标志码:B

Analysis of pipe punching process and mold optimization design

Abstract: Taking the bracket part made of hollow pipe as an example, the structural characteristics of the part are introduced, and the punching process of the bracket part is analyzed. By establishing a mathematical model, the correlation between the punching size and the diameter of the pipe and other relevant sizes is analyzed, and the influencing factors of the strength of the hollow pipe after punching are analyzed, so as to realize the optimization design of the products in the application of hollow pipes.

Key words: hollow pipe; punched hole; process analysis; optimization

0 引 言

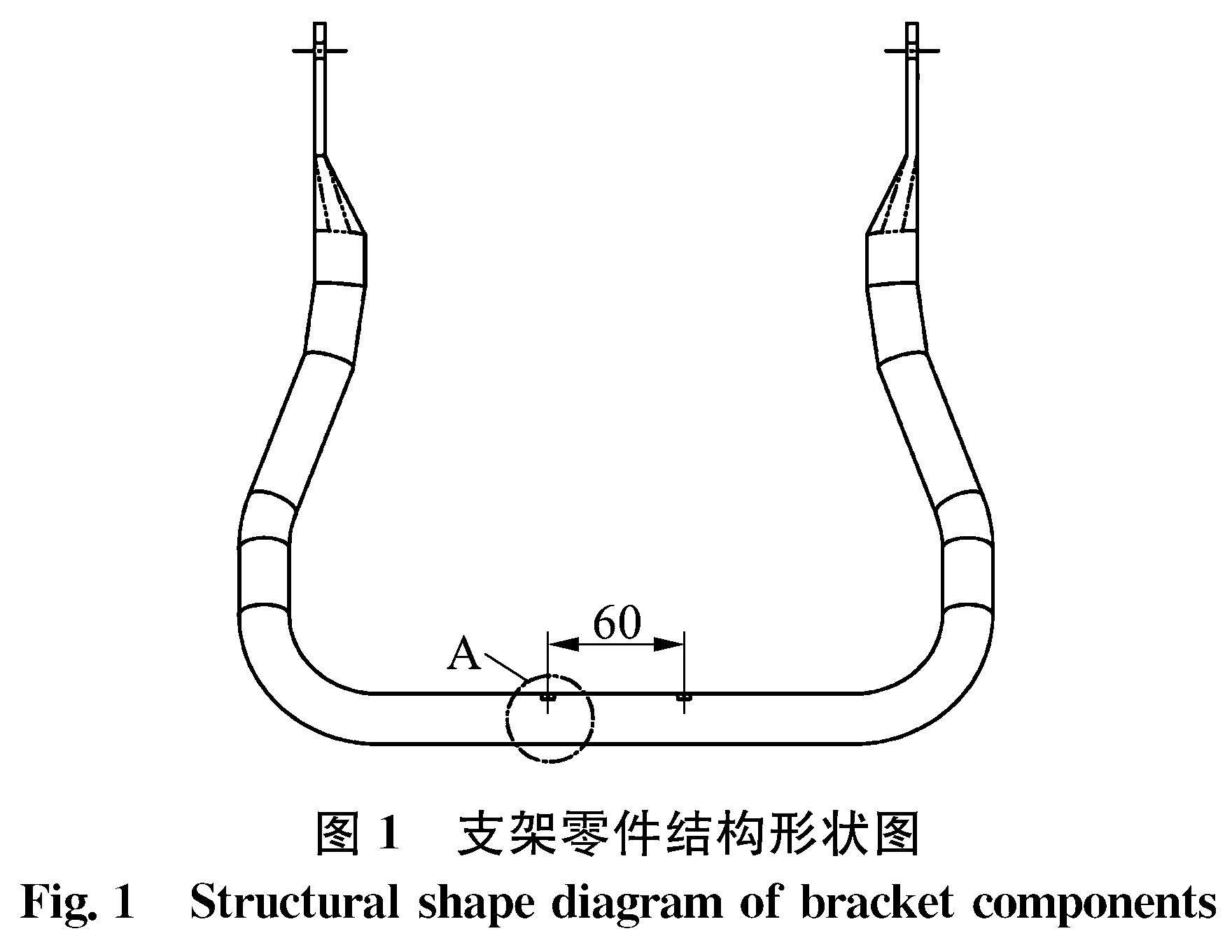

某型号支架零件的结构形状如图1所示,产品零件的材质为Q235,是壁厚t=2.0mm的管材产品零件,管材外径为38.0mm;支架零件上有两个连接安装使用的孔,直径5.0mm;管材内外径尺寸均匀,弯曲处为生产时的自然圆角过渡,两个U形管管口处为扁平贴合的成型结构形式。(剩余4471字)