微合金钢连铸板坯表面裂纹的成因与防止措施

打开文本图片集

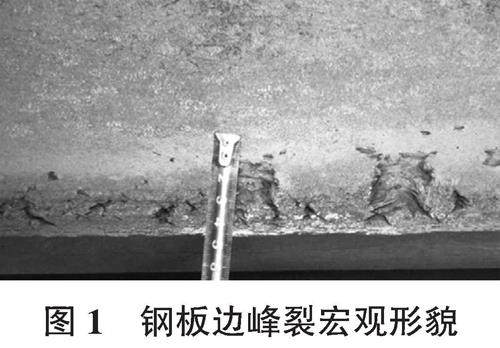

摘 要:结合生产实际,分别采用光谱分析仪、金相显微镜、扫描电镜及能谱仪对铸坯与板材表面裂纹处的化学成分、金相组织、显微形貌及夹杂物成分进行分析,并对生产工艺进行调查研究,确定钢板裂纹在连铸-加热-轧制过程中的形成机理,从而提出进一步降低板坯裂纹的可行性建议及工艺优化措施。

关键词:连铸板坯;裂纹缺陷;金相分析;防止措施

CAUSES AND PREVENTIVE MEASURES SURFACE CRACK IN ALLOYED CONTINUOUS CASTING SLAB

Wang Huifeng

(Hebei Yanshan Iron & Steel Co., Ltd. Qianan 064403, China)

Abstract:Combined with the actual production,spectrum analyzer,metallographic microscope, scanning electron microscope and energy spectrometer were apployed on the analysed of micro alloy steel continuous casting slab surface crack formation mechanism and solving measures and carries on the investigation and study to the production process, determine the steel plate crack in continuous casting - heat - forming mechanism in the process of rolling,to further reduce the feasibility of slab crack advice and process optimization measures.

Key words:continuous cast slab;crack defect;metallographic analysis;preventive measures

0 前 言

河北燕山钢铁集团有限公司板坯连铸机是直结晶器连续弯曲连续矫直弧形板坯连铸机,其基本半径R为9.5 m,厚度规格230 mm,宽度在900~1 630 mm。(剩余3430字)