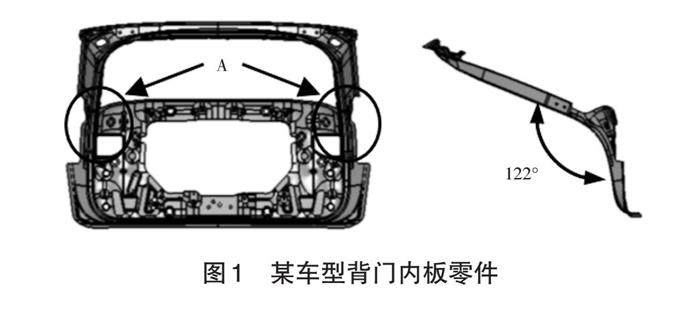

基于AutoForm分析的铝板背门内板成形性能研究

打开文本图片集

摘要:为解决铝板材料成型性和延展性差、背门内板产品形状复杂导致铝板背门内板设计及生产困难的问题,基于AutoForm有限元软件在理论上对铝板背门内板成形性进行模拟分析,通过对不同方案的模拟分析,确定最终成形方案并指导现场生产,同时在现场调试中得到验证。

关键词:汽车轻量化 铝板 背门内板 AutoForm CAE模拟

中图分类号:U466 文献标志码:B DOI: 10.19710/J.cnki.1003-8817.20230118

Research on the Formability of Aluminum Sheet Rear Door Inner Plate Based on AutoForm Analysis

Zhao Hui, Li Kai, Zhang Xiongfei, Song Tieming, Hu Yong

(FAW Tooling Die Manufacturing Co., Ltd., Changchun 130013)

Abstract: To address the issue of difficulty in designing and producing aluminum plate rear door inner plate caused by poor formability and ductility of aluminum plate material, complex shape of rear door inner plate, this paper introduced the simulation analysis of the formability of aluminum plate back door inner plates theoretically based on AutoForm finite element software. Through simulation analysis of different solutions, the final forming solution was determined which guided on-site production, and was verified in on-site debugging.

Key words: Automobile lightweight, Aluminium sheet, Rear door inner plate, AutoForm, CAE simulation

1 前言

隨着全球汽车保有量的逐年增加,汽车已经成为造成全球性温室效应及能源极度消耗的原因之一,根据相关研究,汽车质量每减轻10%,油耗降低6%~8%,碳排放减少4%,而白车身质量约占整车质量的40%,车身轻量化对于降低轿车整备质量具有重要作用[1-2]。(剩余4182字)

网站仅支持在线阅读(不支持PDF下载),如需保存文章,可以选择【打印】保存。